When the heat is on, a functioning Car Aircon system is more than a luxury—it’s a necessity. While many drivers simply want their car air conditioning to work without delving into the mechanics, understanding the basics can be beneficial for maintenance and troubleshooting.

Car air conditioning systems operate by cycling refrigerant between liquid and gas states. This process effectively absorbs heat and humidity from inside the car, releasing cool, dry air in its place. The refrigerants used in these systems have evolved over time, from the older R-12 (Freon) to R-134a, and now increasingly to R-1234yf, which is designed to reduce environmental impact by producing fewer greenhouse gases.

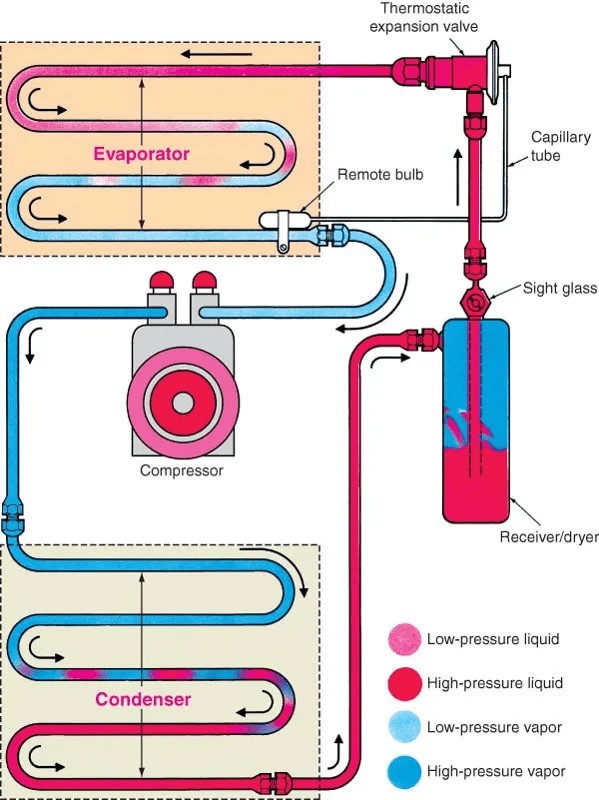

A car aircon system is composed of several key parts, including the compressor, condenser, dryer, metering device, and evaporator. Each component plays a critical role in the cooling cycle. Common issues that can disrupt car aircon performance range from refrigerant leaks, which can severely damage the compressor, to blockages in the condenser caused by road debris and dirt, hindering airflow. Automotive AC technicians are specialists in diagnosing and repairing these systems, making it a crucial skill within the automotive service industry.

For those curious about the inner workings of their car’s AC, this article will explore the theory behind air conditioning, detail the system components, and explain the operational process.

How Does Car Aircon Work?

The fundamental principle behind a car aircon system is the manipulation of refrigerant between liquid and gaseous states. This transition is the key to heat absorption and the subsequent release of cool air. As the refrigerant changes state within the sealed system, it draws heat and moisture out of the vehicle’s cabin air, enabling the system to blow out cooler and drier air.

To facilitate these state changes in the refrigerant, the car aircon system precisely controls both pressure and temperature throughout its cycle. This controlled manipulation is what allows for efficient cooling.

Car Aircon Refrigerants: A History of Innovation

In the early days of automotive air conditioning, R-12, commonly known as Freon, was the industry standard refrigerant. R-12 was lauded for its effectiveness as a CFC-based refrigerant. It was non-flammable and considered non-toxic to humans. However, in the late 1980s, scientific research revealed that the widespread use of R-12 was significantly contributing to the depletion of the Earth’s ozone layer.

In response to environmental concerns, the automotive industry transitioned to R-134a in the mid-1990s. R-134a is an HFC-based refrigerant that does not possess the ozone-damaging properties of Freon. More recently, the industry is moving towards R-1234yf, which is designed to produce fewer greenhouse gases, further minimizing environmental impact. Europe has already mandated the use of R-1234yf, and it is expected to become the new standard in the United States as well.

If a car aircon system loses its cooling efficiency, one common solution is to recharge the system with new refrigerant. This process, typically performed by a trained technician, involves replenishing the refrigerant levels to restore optimal cooling performance.

Key Components of a Car Aircon System

Automotive air conditioning systems are composed of several essential components, each playing a vital role in the cooling process. Below are the main parts of a car aircon system and their functions:

Compressor

- Acts as the power unit of the entire system, creating a pressure differential between the low-pressure and high-pressure sides.

- Compresses low-pressure refrigerant gas, converting it into high-temperature, high-pressure gas.

- Typically mounted at the front of the engine and driven by the serpentine belt, drawing mechanical power from the engine.

Condenser

- Responsible for reducing the temperature of the high-pressure refrigerant gas.

- Facilitates the phase change of the refrigerant from a gaseous state to a liquid state as it cools down.

- Operates similarly to an engine radiator, using forced air, either from a fan or vehicle movement, to dissipate heat.

- Positioned at the front of the vehicle, usually behind the grille, to maximize airflow.

Dryer (Receiver-Dryer)

- Functions to remove moisture from the refrigerant using a desiccant, a specialized drying agent.

- Also provides a degree of filtration, removing particulate contaminants from the system.

- Located on the high-pressure side of the system, typically between the condenser and the metering device.

Metering Device (Expansion Valve or Orifice Tube)

- Serves to reduce the pressure of the liquid refrigerant significantly, which in turn causes a rapid drop in refrigerant temperature.

- The refrigerant remains in a liquid state as it exits the metering device, but at a much lower pressure and temperature.

- Positioned on the high-pressure side, between the dryer and the firewall, just before the evaporator.

Evaporator

- This is where the low-pressure liquid refrigerant undergoes a phase change back to a gaseous state. This evaporation process absorbs heat, creating a cooling effect.

- As cabin air is blown across the evaporator, it is cooled and dehumidified, providing cool, dry air into the vehicle.

- Uniquely positioned inside the passenger compartment, typically behind the dashboard, to directly cool the cabin air.

Path and Characteristics of Refrigerant

- Refrigerant enters the compressor as a low-temperature, low-pressure gas.

- Exits the compressor as a high-temperature, high-pressure gas.

- In the condenser, it cools and transitions into a high-pressure liquid.

- The receiver/dryer then removes any moisture from the high-pressure liquid refrigerant.

- The expansion valve reduces the pressure of the refrigerant.

- Finally, in the evaporator, the refrigerant converts back to a low-pressure gas.

- This evaporation process absorbs heat, and as air is blown across the evaporator, it becomes cool and dry.

Car Aircon System Diagram

The diagram below illustrates the main components of a typical car aircon system and their interconnections:

Diagram of a car air conditioning system showing compressor, condenser, dryer, metering device, and evaporator

Diagram of a car air conditioning system showing compressor, condenser, dryer, metering device, and evaporator

Common Car Aircon System Problems

Car air conditioning systems are designed to operate under pressure and must maintain a completely sealed environment. Any breach that allows refrigerant to escape or contaminants to enter can lead to system failure.

A refrigerant leak, no matter how small, will impair the system’s ability to cool effectively. Simply adding more refrigerant without addressing the leak is only a temporary solution. To properly repair a leaking system, it’s essential to locate and fix the leak, replace any damaged components, and then evacuate and recharge the system to the correct refrigerant level.

Refrigerant leaks not only diminish cooling performance but can also cause significant damage to the compressor. Running the compressor with insufficient refrigerant can lead to overheating and internal damage. Compressors are typically sealed units and are not designed for servicing, making replacement the usual—and costly—remedy.

Another common issue is reduced airflow through the condenser. The condenser requires a consistent flow of air across its fins to dissipate heat effectively. Road debris, dirt, and even insects can accumulate on the condenser, obstructing airflow and reducing system efficiency. Because the condenser is located at the front of the vehicle, behind the grille, it is particularly vulnerable to blockage. Regular inspection and cleaning of the condenser can help prevent these issues.

What This Means for Your Career in Automotive Technology

Air conditioning has transitioned from a luxury to a standard feature in nearly every new car sold today in the U.S. This widespread adoption has created a consistent demand for skilled automotive AC technicians. These professionals are regularly needed at both dealerships and independent repair shops to diagnose and repair car aircon systems. Technicians frequently encounter customer complaints ranging from inadequate cooling and unusual noises to water leaks inside the vehicle.

For individuals considering a career in the automotive industry, specializing in car aircon systems can be a rewarding and stable path. The increasing complexity of automotive technology and the essential nature of air conditioning in modern vehicles ensure a continued need for knowledgeable and skilled technicians.

Car Aircon System FAQs

How does a car air conditioner work?

A car air conditioner cools air using a compressor to increase the pressure and temperature of the refrigerant. This high-pressure refrigerant then moves to the condenser to dissipate heat, then to other components to ultimately cool the air blown into the car. The process involves phase changes of the refrigerant to absorb and release heat.

What are the main components of a car air conditioning system?

The primary components of a car aircon system include:

- Compressor

- Condenser

- Evaporator

- Receiver-dryer (or Dryer)

- Expansion valve (or Orifice tube)

Each part plays a critical role in the refrigerant cycle that enables cooling.

How does the refrigerant in a car air conditioner cool the air?

Refrigerant cools air by changing from a liquid to a gas in the evaporator. This phase change requires heat, which the refrigerant absorbs from the air passing over the evaporator. As air is forced across the evaporator, the refrigerant absorbs heat, causing the air to become cooler and drier before it enters the vehicle cabin.

Train To Become an Automotive Technician

Is a career as an automotive technician appealing to you? At Universal Technical Institute (UTI), students receive comprehensive training across all vehicle systems, including advanced car air conditioning technology.

In under a year, you can acquire the necessary skills and knowledge to begin your career in the automotive field. To explore this opportunity further, visit our program page and request information to connect with an Admissions Representative.

Our Campuses That Offer Automotive Technician Training

YOU COULD START YOUR EXCITING NEW CAREER AS A MECHANIC OR TECHNICIAN TODAY.

With classes starting every 3-6 weeks, you don’t have to wait to begin your career.

Hands-on training. Gain practical experience with leading industry brands.

No Pressure to commit. Get all your questions answered without obligation.

Related Articles

[

How Long Does It Take to Become an Automotive Mechanic?](/blog/education/automotive-technician-career)How long does it take to become an auto mechanic? Explore this role and how to pursue a career in the industry with training from UTI!

[

What Is an Automotive Service Writer and What Do They Do?](/blog/automotive/automotive-service-writer)Learn about the automotive service writer job description, how to become a service writer, and career paths.

[

The Automotive Technician Shortage: What Does This Mean for Your Career?](/blog/automotive/automotive-tech-shortage)Understand the automotive technician shortage and its implications for your career opportunities.

1 ) UTI is an educational institution and cannot guarantee employment or salary.

2 ) For program outcome information and other disclosures, visit www.uti.edu/disclosures.

7 ) Some programs may require longer than one year to complete.

Universal Technical Institute of Illinois, Inc. is approved by the Division of Private Business and Vocational Schools of the Illinois Board of Higher Education.