Model train enthusiasts often strive for realism in their layouts, and lighting in passenger cars and cabooses is a crucial element. However, flickering lights can detract from the overall effect, especially when trains pass over unpowered track sections or gaps. This article delves into a simple yet effective solution to achieve flicker-free Car Lighting in your model trains, focusing on a cost-efficient and easy-to-implement approach using readily available components.

Basic Circuit Diagram for Flicker-Free Model Car Lighting

Understanding the Flicker in Model Train Car Lighting

The frustrating flicker in model train car lighting, whether using LEDs or incandescent bulbs, occurs because of brief power interruptions. These interruptions can be caused by unpowered frogs in track switches, dirty track sections, or gaps in the rails. LEDs, known for their rapid on/off response, make this flickering more noticeable compared to incandescent lamps. While solutions exist for DCC decoders to maintain locomotive power, this discussion focuses solely on car lighting and eliminating flicker within the cars themselves. To prevent these annoying light outages, the LEDs or lamps need a continuous power source even when track power is temporarily lost. This is where stored energy solutions come into play.

Traditional Approaches to Flicker-Free Car Lighting

Model railroaders have employed various methods to tackle flickering car lighting. Batteries and capacitors are common energy storage devices utilized for this purpose. Beyond battery power, several prior techniques have emerged:

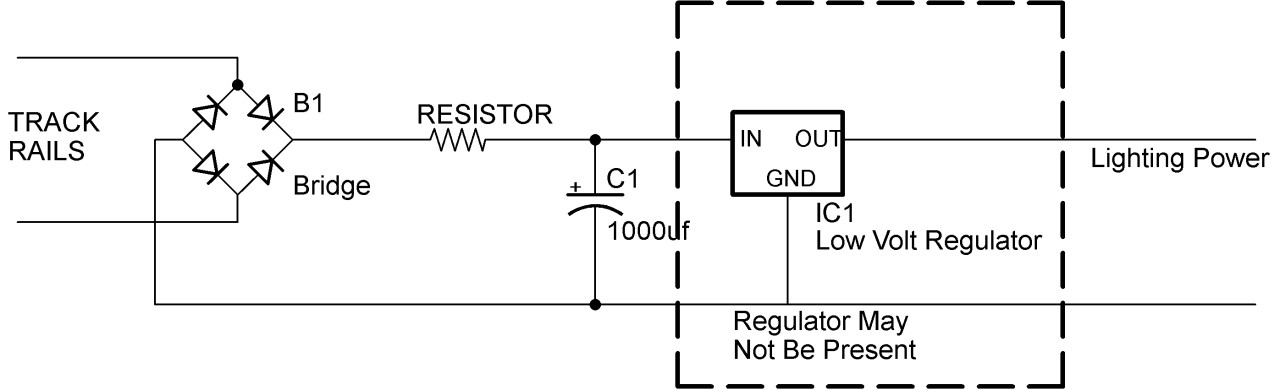

- Resistor and Large Capacitor Circuits: This basic approach uses a resistor and a substantial capacitor, sometimes incorporating a voltage regulator, to store energy and provide power during interruptions.

- Super Capacitor Circuits: Similar to the previous method, but employing a supercapacitor, with or without a voltage regulator, for enhanced energy storage capacity.

These circuits typically utilize a small diode bridge connected to the track power to convert AC track voltage into DC voltage for charging the capacitor and powering the car lighting. While these methods offer improvements, they often have limitations in terms of size, cost, and effectiveness, especially when powering multiple LEDs in passenger cars or cabooses.

Introducing a Game-Changing Technology: Switching Regulators

A significant advancement in achieving consistent car lighting is the adoption of switching regulators, also known as DC-DC converters. Unlike traditional linear voltage regulators, switching regulators function as DC-DC converters with remarkable efficiency, often reaching around 96%. This high efficiency is crucial in maximizing the use of stored energy for car lighting.

While switching regulators were once complex and expensive, the development of integrated circuits has revolutionized their accessibility and size. These compact ICs integrate nearly all necessary functions, making switching regulators a practical and cost-effective solution for model train car lighting. Examples of their application can be found in articles like “Battery Powered Models in HO Scale” from the November 2014 issue of Model Railroad Hobbyist (MRH).

Compact and Affordable DC-DC Converter/Voltage Regulator for Model Car Lighting

Simple and Cost-Effective Components for Flicker-Free Lighting

For a straightforward and budget-friendly flicker-free car lighting solution, only three main components are required:

- Mini DIP Bridge Rectifier: A 1/2A 400V mini DIP bridge rectifier, such as the allelectromics.com CAT # FWB-16 (.40), converts AC track power to DC.

- DC-DC Converter: A 3A DC-DC Converter Adjustable Step-down Power Supply Module (.96) efficiently regulates voltage for the car lighting LEDs. These can be found on platforms like eBay (e.g., item #291353891841).

- Capacitor: An Aluminum Electrolytic Capacitor, either 1000uF 25V 20% RADIAL (Digikey 493-1305-ND .51) or 2200uF 25V 20% RADIAL (Digikey P5157-ND .90), stores energy to maintain car lighting during power interruptions. For G gauge DCC with higher voltage, a 35V capacitor is recommended.

These readily available and inexpensive components form the core of a highly effective flicker-free car lighting system.

Assembling Your Flicker-Free Car Lighting Circuit

Constructing the circuit is remarkably simple. Solder the capacitor across the input terminals of the DC-DC converter, ensuring correct polarity (+ to + and – to -). Similarly, connect the positive and negative outputs of the bridge rectifier to the corresponding input terminals of the DC-DC converter, again observing proper polarity.

Crucially, before connecting the module to your model car lighting, you must adjust the output voltage of the DC-DC converter. Use the trim potentiometer (a small circular component on the module) to set the voltage as low as possible while still adequately powering your LEDs. Different colored LEDs have varying voltage requirements. For white LEDs, an output of around 2.8 volts is typically suitable, often used with a series resistor (e.g., 47 ohms for 4-6 white LEDs) to fine-tune the current. Adjust the voltage before connecting to your model to avoid potential damage to your LEDs. The potentiometer has no stops, so exercise caution during adjustment.

Components and Assembled Units for Flicker-Free Car Lighting using 1000uF and 2200uF Capacitors

Compact 1000uF Keep-Alive Unit for Flicker-Free Car Lighting

How Switching Regulators Ensure Flicker-Free Lighting

The track voltage serves as the primary energy source for car lighting. The capacitor in the circuit stores energy charged from the track voltage after rectification into DC. The switching regulator then steps down this voltage to the optimal level for the LEDs with exceptional efficiency.

The key advantage of the switching regulator is its ability to maintain a stable output voltage even as the capacitor discharges. It efficiently tracks the declining voltage and continues to provide the correct voltage for the car lighting, ensuring consistent and flicker-free illumination.

With a 2200uF capacitor at DCC voltage, a keep-alive time of approximately 3 seconds for 35mA car lighting load can be achieved. A 1000uF capacitor provides around 1 second of keep-alive. These durations are approximate and depend on factors like track voltage and LED current draw.

For DC powered layouts, lower track voltages (6-9 volts) are common. The DC-DC converter requires a voltage input roughly 3 volts higher than the set output voltage to function effectively. Higher track voltage and larger capacitors will extend the keep-alive duration, even in DC or variable voltage AC systems.

Tiny DC-DC Converter Option for Space-Constrained Model Cars

Size Comparison of Components for Model Car Lighting Flicker Suppression

Conclusion: Enjoy Consistent Car Lighting on Your Layout

By utilizing a simple circuit with a switching regulator, diode bridge, and capacitor, you can effectively eliminate flickering in your model train car lighting. This cost-effective and easy-to-assemble solution enhances the realism and enjoyment of your model railroad. Experiment with capacitor sizes to achieve the desired keep-alive duration for your specific layout and car lighting needs. Illuminate your passenger cars and cabooses with confidence and say goodbye to annoying flicker!