Geo Car technology is transforming railway maintenance, and CARS.EDU.VN is your ultimate resource for understanding this innovation. Explore how these advanced systems enhance rail safety and efficiency, providing crucial insights for rail professionals and enthusiasts alike. Discover more about railway safety and predictive maintenance at CARS.EDU.VN.

1. Understanding Geo Car Technology: An Overview

Geo car technology represents a significant leap forward in railway infrastructure maintenance and safety. These specialized vehicles, equipped with an array of sophisticated sensors and imaging systems, are designed to assess the condition of railway tracks and related components in real-time. The primary goal of geo car operations is to identify potential defects, anomalies, and areas of concern that could compromise the safety and efficiency of rail transport.

The evolution of geo car technology has been remarkable, progressing from basic visual inspections to highly automated and data-driven assessments. Early methods relied heavily on human observation and manual measurements, which were time-consuming and prone to errors. Modern geo cars, however, leverage advanced technologies such as:

- High-Resolution Cameras: These cameras capture detailed images of the track and its surroundings, enabling the detection of surface defects, misalignments, and other visual indicators of potential problems.

- Laser Measurement Systems: Lasers are used to precisely measure track geometry, including rail alignment, curvature, and cross-level. These measurements are critical for identifying deviations from design specifications that could lead to derailments or other safety incidents.

- Ground-Penetrating Radar (GPR): GPR technology allows for the non-destructive assessment of the track substructure, including the ballast, subgrade, and underlying soil. This is essential for identifying hidden issues such as voids, moisture intrusion, and instability that could affect track integrity.

- Infrared Thermography: Infrared cameras detect thermal anomalies in rails, joints, and other components, indicating potential issues such as cracks, corrosion, or electrical faults.

- Acoustic Monitoring: Acoustic sensors listen for unusual sounds that could indicate defects in bearings, wheels, or other mechanical components of passing trains.

By integrating these technologies, geo cars can collect vast amounts of data as they traverse the railway network. This data is then processed using advanced algorithms and machine learning techniques to identify patterns, anomalies, and potential risks. The results are used to prioritize maintenance activities, schedule repairs, and optimize resource allocation, all aimed at ensuring the safe and efficient operation of the railway system. CARS.EDU.VN offers in-depth analysis of these technologies, providing valuable insights for industry professionals and anyone interested in the future of rail transport.

2. The Crucial Role of Geo Cars in Railway Safety

Railway safety is paramount, and geo cars play a vital role in upholding the integrity of rail networks. These specialized vehicles conduct comprehensive inspections, identifying potential hazards before they escalate into serious incidents. By detecting defects, misalignments, and other anomalies, geo cars enable proactive maintenance, ensuring that trains operate safely and reliably.

One of the primary functions of geo cars is to assess track geometry. Deviations from specified parameters can lead to derailments, especially at high speeds. Geo cars use laser measurement systems to precisely measure track alignment, curvature, and cross-level, identifying any deviations that need correction. These measurements help maintenance teams address issues before they become critical, preventing accidents and ensuring smooth operations.

Geo cars also play a critical role in detecting defects in rails, joints, and other track components. High-resolution cameras and infrared thermography are used to identify cracks, corrosion, and other signs of wear and tear. Early detection of these defects allows for timely repairs, preventing rail breaks and ensuring the structural integrity of the track. The Track Health Optical Recognition (THOR) system, for example, can detect cracks as small as one-sixteenth of an inch, enabling proactive maintenance.

Ground conditions are another critical factor in railway safety. The stability of the ballast, subgrade, and underlying soil is essential for maintaining track integrity. Geo cars use ground-penetrating radar (GPR) to assess the condition of these subsurface layers, identifying voids, moisture intrusion, and other issues that could compromise track stability. This information helps maintenance teams address ground-related problems before they lead to track deformation or failure.

The data collected by geo cars is processed using advanced algorithms and machine learning techniques, enabling predictive maintenance. By analyzing trends and patterns, these systems can forecast when and where maintenance is needed, optimizing resource allocation and minimizing downtime. This proactive approach to maintenance ensures that the railway network remains safe and reliable, reducing the risk of accidents and disruptions. At CARS.EDU.VN, we provide detailed insights into how geo cars contribute to railway safety, offering valuable information for both professionals and enthusiasts.

3. The Technology Behind Geo Cars: Sensors and Systems

The effectiveness of geo cars lies in the sophisticated technology they employ. These specialized vehicles are equipped with an array of sensors and systems that work in concert to assess the condition of railway tracks and related components. Understanding these technologies is key to appreciating the capabilities of geo cars and their impact on railway safety and efficiency.

- High-Resolution Cameras: Geo cars use high-resolution cameras to capture detailed images of the track and its surroundings. These cameras are capable of detecting surface defects, misalignments, and other visual indicators of potential problems. The images are analyzed using computer vision algorithms to automatically identify and classify defects, providing maintenance teams with precise information about the location and severity of each issue.

- Laser Measurement Systems: Laser measurement systems are used to precisely measure track geometry, including rail alignment, curvature, and cross-level. These systems use lasers to scan the track surface and measure its position relative to a reference point. The measurements are accurate to within millimeters, allowing for the detection of even small deviations from design specifications.

- Ground-Penetrating Radar (GPR): GPR technology is used to assess the condition of the track substructure, including the ballast, subgrade, and underlying soil. GPR works by emitting radio waves into the ground and measuring the reflected signals. The reflected signals provide information about the composition and structure of the subsurface layers, allowing for the identification of voids, moisture intrusion, and other issues that could affect track stability.

- Infrared Thermography: Infrared cameras are used to detect thermal anomalies in rails, joints, and other components. These cameras measure the temperature of the track surface and create thermal images that highlight areas of elevated temperature. Thermal anomalies can indicate potential issues such as cracks, corrosion, or electrical faults.

- Acoustic Monitoring: Acoustic sensors are used to listen for unusual sounds that could indicate defects in bearings, wheels, or other mechanical components of passing trains. These sensors are placed along the track and are capable of detecting sounds that are inaudible to the human ear. The sounds are analyzed using signal processing techniques to identify patterns that are indicative of specific types of defects.

These sensors and systems work together to provide a comprehensive assessment of track condition. The data collected by the geo car is processed using advanced algorithms and machine learning techniques to identify patterns, anomalies, and potential risks. The results are used to prioritize maintenance activities, schedule repairs, and optimize resource allocation. CARS.EDU.VN offers detailed explanations of these technologies, providing valuable insights for industry professionals and anyone interested in the future of rail transport.

4. Enhancing Efficiency with Geo Cars: Maintenance and Operations

Geo cars not only enhance railway safety but also significantly improve the efficiency of maintenance and operations. By providing real-time data on track conditions, these vehicles enable proactive maintenance, reducing downtime and optimizing resource allocation. The insights gained from geo car inspections allow railway operators to make informed decisions, ensuring smooth and cost-effective operations.

One of the key benefits of geo cars is their ability to identify potential problems before they escalate into major issues. This proactive approach to maintenance reduces the need for emergency repairs, minimizing disruptions to train schedules and reducing overall maintenance costs. By detecting defects early, geo cars enable maintenance teams to address issues in a timely and efficient manner, preventing costly downtime.

Geo cars also optimize resource allocation by providing detailed information on track conditions. This information allows maintenance teams to prioritize their efforts, focusing on areas that require immediate attention. By targeting maintenance activities to specific locations, railway operators can reduce the amount of time and resources spent on unnecessary inspections and repairs. This targeted approach to maintenance ensures that resources are used effectively, maximizing the return on investment.

The data collected by geo cars is used to develop predictive maintenance models, enabling railway operators to forecast when and where maintenance is needed. These models analyze trends and patterns in the data to identify potential problems before they occur. By predicting maintenance needs, railway operators can schedule repairs in advance, minimizing disruptions to train schedules and reducing the risk of unexpected downtime.

Geo cars also improve the efficiency of track inspections. Traditional track inspections are time-consuming and labor-intensive, requiring teams of workers to walk along the track and visually inspect its condition. Geo cars automate this process, allowing for faster and more comprehensive inspections. By covering large distances in a short amount of time, geo cars can inspect entire railway networks quickly and efficiently.

In addition to improving maintenance and operations, geo cars also contribute to energy efficiency. By ensuring that tracks are in good condition, these vehicles help to reduce rolling resistance, which can significantly impact fuel consumption. Well-maintained tracks allow trains to operate more efficiently, reducing energy costs and minimizing environmental impact. CARS.EDU.VN offers detailed insights into how geo cars enhance railway efficiency, providing valuable information for both professionals and enthusiasts.

5. Benefits of Geo Car Technology

| Benefit | Description |

|---|---|

| Enhanced Safety | Identifies potential hazards early, preventing accidents and ensuring safe train operations. |

| Reduced Downtime | Proactive maintenance minimizes disruptions to train schedules and reduces the need for emergency repairs. |

| Optimized Resource Allocation | Detailed track condition data allows for targeted maintenance, reducing unnecessary inspections and repairs. |

| Predictive Maintenance | Data analysis enables forecasting of maintenance needs, allowing for scheduled repairs and minimizing unexpected downtime. |

| Improved Inspection Efficiency | Automates track inspections, covering large distances quickly and efficiently compared to traditional methods. |

| Energy Efficiency | Well-maintained tracks reduce rolling resistance, leading to lower fuel consumption and reduced environmental impact. |

| Cost Savings | Proactive maintenance and optimized resource allocation result in significant cost savings over time. |

| Extended Asset Life | Regular inspections and timely repairs extend the lifespan of track and related infrastructure. |

| Data-Driven Decision Making | Real-time data on track conditions enables informed decisions, ensuring smooth and cost-effective operations. |

| Regulatory Compliance | Ensures compliance with safety regulations and standards, reducing the risk of penalties and legal issues. |

6. The Evolution of Geo Car Technology

The evolution of geo car technology has been a remarkable journey, transforming railway maintenance from manual inspections to automated, data-driven assessments. This evolution has been driven by advances in sensor technology, data processing, and machine learning, resulting in safer, more efficient, and cost-effective railway operations.

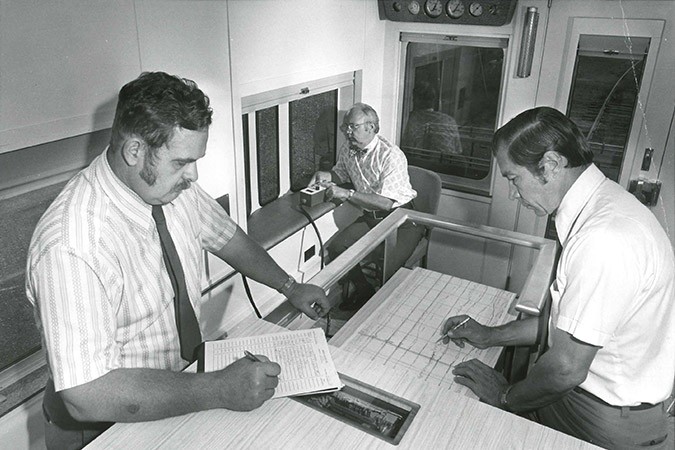

In the early days of railway maintenance, track inspections relied heavily on human observation. Teams of workers would walk along the tracks, visually inspecting the rails, joints, and other components for defects. This method was time-consuming, labor-intensive, and prone to errors. The accuracy of the inspections depended on the experience and vigilance of the workers, and it was difficult to detect subtle defects or subsurface issues.

The introduction of geometry cars in the mid-20th century marked a significant step forward. These specialized vehicles were equipped with mechanical sensors that measured track geometry, including rail alignment, curvature, and cross-level. The measurements were recorded on strip charts, which were then manually reviewed by engineers to identify deviations from specified parameters. While geometry cars improved the efficiency of track inspections, they still required significant human involvement.

The advent of computers and electronics in the late 20th century led to the development of more advanced geo car technologies. High-resolution cameras, laser measurement systems, and ground-penetrating radar (GPR) were integrated into geo cars, allowing for the collection of vast amounts of data on track conditions. This data was processed using algorithms and software to automatically identify defects, anomalies, and potential risks.

The 21st century has seen further advances in geo car technology, driven by the rise of artificial intelligence and machine learning. These technologies enable geo cars to analyze data in real-time, identify patterns, and predict maintenance needs. The Track Health Optical Recognition (THOR) system, for example, uses machine vision algorithms to automatically detect defects on rail joints, such as missing bolts or cracks.

Today, geo cars are equipped with a wide range of sensors and systems that provide a comprehensive assessment of track condition. These vehicles can operate at speeds up to 70 mph, covering large distances in a short amount of time. The data collected by geo cars is used to prioritize maintenance activities, schedule repairs, and optimize resource allocation, all aimed at ensuring the safe and efficient operation of the railway system. At CARS.EDU.VN, we explore the history and future of geo car technology, providing valuable insights for industry professionals and anyone interested in the evolution of rail transport.

7. Geo Car Applications: Beyond Track Inspection

While track inspection is the primary application of geo cars, these versatile vehicles can be used for a variety of other purposes. The sensors and systems onboard geo cars can collect data on a wide range of parameters, providing valuable insights for railway operators and infrastructure managers. By leveraging the capabilities of geo cars, railway organizations can improve safety, efficiency, and sustainability.

- Vegetation Management: Geo cars can be used to monitor vegetation along railway tracks. Overgrown vegetation can obstruct visibility, interfere with train operations, and pose a fire hazard. Geo cars equipped with high-resolution cameras and LiDAR systems can identify areas where vegetation needs to be trimmed or removed. This information can be used to prioritize vegetation management activities, reducing the risk of accidents and improving operational efficiency.

- Asset Inventory: Geo cars can be used to create a detailed inventory of railway assets, including tracks, bridges, tunnels, signals, and other infrastructure components. The sensors and systems onboard geo cars can collect data on the location, condition, and characteristics of these assets. This information can be used to create a comprehensive database that supports asset management, maintenance planning, and investment decisions.

- Right-of-Way Monitoring: Geo cars can be used to monitor the railway right-of-way for encroachments, unauthorized activities, and other potential threats. High-resolution cameras and LiDAR systems can detect changes in the right-of-way, such as new construction, illegal dumping, or trespassing. This information can be used to take corrective action, protecting railway infrastructure and ensuring the safety of operations.

- Environmental Monitoring: Geo cars can be used to monitor environmental conditions along railway tracks. Sensors can measure air quality, noise levels, and other environmental parameters. This information can be used to assess the environmental impact of railway operations and identify opportunities for improvement.

- Security Monitoring: Geo cars can be used to monitor railway tracks and infrastructure for security threats. High-resolution cameras and thermal imaging systems can detect suspicious activities, such as vandalism, theft, or sabotage. This information can be used to alert security personnel and prevent security incidents.

These are just a few of the many applications of geo cars. As technology continues to advance, new applications will emerge, further enhancing the value of these versatile vehicles. CARS.EDU.VN offers in-depth analysis of geo car applications, providing valuable insights for industry professionals and anyone interested in the future of rail transport.

8. The Future of Geo Car Technology: Trends and Innovations

The future of geo car technology is bright, with ongoing advancements promising to enhance railway safety, efficiency, and sustainability even further. Emerging trends and innovations are set to transform the way geo cars operate, collect data, and analyze information, leading to more proactive and data-driven railway maintenance practices.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are already playing a significant role in geo car technology, and their importance will only grow in the future. AI-powered algorithms can analyze data in real-time, identify patterns, and predict maintenance needs with greater accuracy. ML techniques can be used to train geo car systems to recognize and classify defects automatically, reducing the need for human intervention.

- Internet of Things (IoT): The IoT is transforming the way railway assets are monitored and managed. Geo cars can be integrated with IoT networks, allowing them to communicate with other devices and systems in real-time. This enables the sharing of data and insights, leading to more coordinated and efficient maintenance activities.

- Autonomous Geo Cars: Autonomous geo cars are being developed that can operate without human intervention. These vehicles use GPS, sensors, and AI to navigate railway tracks and collect data automatically. Autonomous geo cars can operate 24/7, providing continuous monitoring of track conditions and reducing the need for manual inspections.

- Drones: Drones are being used to supplement geo car inspections. Drones can access areas that are difficult or dangerous for geo cars to reach, such as bridges, tunnels, and remote locations. Drones can also be equipped with high-resolution cameras and other sensors, providing detailed images and data on track conditions.

- Big Data Analytics: The data collected by geo cars is becoming increasingly valuable as the volume and variety of data grow. Big data analytics techniques can be used to process and analyze this data, identifying trends, patterns, and correlations that would be impossible to detect manually. This can lead to new insights into railway operations and maintenance, enabling more proactive and data-driven decision-making.

- Cloud Computing: Cloud computing is enabling railway organizations to store and process geo car data more efficiently. Cloud-based platforms provide scalable and secure storage for large volumes of data, as well as access to powerful analytics tools. This allows railway organizations to analyze geo car data from anywhere in the world, collaborating with colleagues and partners to improve railway safety and efficiency.

These are just a few of the many trends and innovations that are shaping the future of geo car technology. As technology continues to advance, geo cars will become even more powerful and versatile, playing an increasingly important role in ensuring the safety, efficiency, and sustainability of railway operations. Stay informed about these developments and more at CARS.EDU.VN.

9. Implementing Geo Car Technology: Key Considerations

Implementing geo car technology requires careful planning and consideration to ensure successful integration and optimal results. Railway organizations must address various factors, from selecting the right technology to training personnel and establishing data management protocols. A well-thought-out implementation strategy is essential for maximizing the benefits of geo cars and achieving desired outcomes.

- Technology Selection: Selecting the right geo car technology is crucial. Railway organizations must evaluate their specific needs and requirements, considering factors such as track conditions, traffic volume, and budget constraints. It is important to choose a technology that is compatible with existing systems and infrastructure, and that provides accurate and reliable data.

- Data Management: Geo cars generate large volumes of data, which must be managed effectively. Railway organizations need to establish data management protocols that ensure data quality, security, and accessibility. This includes developing procedures for data collection, storage, processing, and analysis.

- Personnel Training: Implementing geo car technology requires trained personnel who can operate the vehicles, interpret the data, and make informed decisions. Railway organizations must invest in training programs that provide employees with the skills and knowledge they need to use geo car technology effectively.

- Integration with Existing Systems: Geo car technology must be integrated with existing railway systems, such as asset management, maintenance planning, and train control. This requires careful coordination and communication between different departments and stakeholders.

- Cost-Benefit Analysis: Implementing geo car technology involves significant upfront costs. Railway organizations must conduct a cost-benefit analysis to determine whether the investment is justified. This analysis should consider the potential benefits of geo cars, such as improved safety, reduced downtime, and optimized resource allocation, as well as the costs of implementation and maintenance.

- Regulatory Compliance: Implementing geo car technology must comply with all applicable regulations and standards. Railway organizations must ensure that their geo car operations meet the requirements of regulatory agencies, such as the Federal Railroad Administration (FRA) in the United States.

- Continuous Improvement: Implementing geo car technology is an ongoing process. Railway organizations must continuously monitor their geo car operations, identify areas for improvement, and make adjustments as needed. This includes regularly evaluating the performance of geo car systems, updating data management protocols, and providing ongoing training for personnel.

By addressing these key considerations, railway organizations can successfully implement geo car technology and reap the many benefits it offers. CARS.EDU.VN provides expert guidance on implementing geo car technology, helping railway organizations make informed decisions and achieve optimal results.

10. Real-World Examples: Geo Cars in Action

To illustrate the impact of geo car technology, let’s examine real-world examples of how these vehicles are being used to improve railway safety and efficiency around the world. These case studies demonstrate the versatility and effectiveness of geo cars in a variety of applications, from track inspection to vegetation management and asset inventory.

Example 1: BNSF Railway

BNSF Railway, one of the largest freight railroad networks in North America, uses geo cars extensively to inspect its 32,500-mile network. BNSF’s geo car fleet includes both manned and unmanned vehicles, equipped with high-resolution cameras, laser measurement systems, and other sensors. The data collected by these vehicles is used to prioritize maintenance activities, schedule repairs, and optimize resource allocation. BNSF has also implemented the Track Health Optical Recognition (THOR) system, which uses machine vision algorithms to automatically detect defects on rail joints. According to BNSF, THOR can detect cracks as small as one-sixteenth of an inch, enabling proactive maintenance and preventing rail breaks.

Example 2: Network Rail (UK)

Network Rail, the owner and operator of the UK’s railway infrastructure, uses geo cars to monitor track conditions and identify potential hazards. Network Rail’s geo car fleet includes a variety of vehicles, equipped with different types of sensors and systems. One of Network Rail’s geo cars is equipped with ground-penetrating radar (GPR), which is used to assess the condition of the track substructure. The GPR data is used to identify voids, moisture intrusion, and other issues that could compromise track stability. Network Rail also uses geo cars to monitor vegetation along railway tracks, identifying areas where vegetation needs to be trimmed or removed.

Example 3: Queensland Rail (Australia)

Queensland Rail, the owner and operator of Queensland’s railway network, uses geo cars to inspect its 6,600-kilometer network. Queensland Rail’s geo car fleet includes a variety of vehicles, equipped with high-resolution cameras, laser measurement systems, and other sensors. Queensland Rail uses geo cars to monitor track geometry, detect defects in rails and joints, and assess the condition of the track substructure. The data collected by these vehicles is used to prioritize maintenance activities, schedule repairs, and optimize resource allocation.

Example 4: SNCF (France)

SNCF, the French national railway company, uses geo cars to inspect its extensive railway network. SNCF’s geo car fleet includes a variety of vehicles, equipped with different types of sensors and systems. SNCF uses geo cars to monitor track geometry, detect defects in rails and joints, and assess the condition of the track substructure. SNCF also uses geo cars to monitor vegetation along railway tracks and to create a detailed inventory of railway assets.

These real-world examples demonstrate the many ways in which geo cars are being used to improve railway safety and efficiency around the world. By providing accurate and reliable data on track conditions, geo cars enable proactive maintenance, reduce downtime, and optimize resource allocation. These benefits translate into safer, more efficient, and more sustainable railway operations. Find more inspiring case studies and best practices at CARS.EDU.VN.

11. Cost-Effectiveness of Geo Car Technology

Investing in geo car technology represents a significant financial commitment for railway organizations. However, the long-term cost-effectiveness of this investment can be substantial, thanks to the numerous benefits that geo cars provide. By improving safety, reducing downtime, optimizing resource allocation, and extending asset life, geo cars can generate significant cost savings over time.

One of the primary ways in which geo cars contribute to cost savings is by improving safety. By identifying potential hazards early, geo cars help to prevent accidents, which can be extremely costly in terms of property damage, injuries, and fatalities. The cost of a single derailment can easily run into millions of dollars, not to mention the reputational damage that can result from a serious accident. By preventing accidents, geo cars help to protect railway organizations from these significant financial losses.

Geo cars also contribute to cost savings by reducing downtime. By enabling proactive maintenance, geo cars help to minimize disruptions to train schedules, which can be costly in terms of lost revenue and customer dissatisfaction. The cost of a single day of downtime can easily run into hundreds of thousands of dollars, depending on the size and complexity of the railway network. By reducing downtime, geo cars help to ensure that trains operate on schedule, maximizing revenue and minimizing disruptions.

Geo cars also optimize resource allocation, leading to further cost savings. By providing detailed information on track conditions, geo cars enable maintenance teams to prioritize their efforts, focusing on areas that require immediate attention. This targeted approach to maintenance reduces the amount of time and resources spent on unnecessary inspections and repairs, ensuring that resources are used effectively.

In addition to these direct cost savings, geo cars also contribute to cost-effectiveness by extending the lifespan of track and related infrastructure. By identifying and addressing defects early, geo cars help to prevent further damage and deterioration. This extends the lifespan of railway assets, reducing the need for costly replacements and upgrades.

Cost Savings through Geo Car Technology

| Area | Description |

|---|---|

| Accident Prevention | Reducing the risk of costly derailments and other accidents, saving on property damage, injuries, and potential fatalities. |

| Reduced Downtime | Minimizing disruptions to train schedules, preserving revenue, and maintaining customer satisfaction. |

| Optimized Resource Allocation | Focusing maintenance efforts on areas needing immediate attention, reducing unnecessary inspections, and utilizing resources efficiently. |

| Extended Asset Lifespan | Identifying and addressing defects early, preventing further damage, and prolonging the life of tracks and infrastructure. |

| Proactive Maintenance | Early detection of potential issues allows for timely repairs, avoiding costly emergency repairs and minimizing long-term expenses. |

| Fuel Efficiency | Ensuring tracks are well-maintained reduces rolling resistance, leading to lower fuel consumption for trains. |

| Data-Driven Decisions | Improving the accuracy and efficiency of decision-making processes, leading to better investments and resource management. |

| Regulatory Compliance | Avoiding penalties and legal issues associated with safety regulation violations through consistent monitoring and maintenance. |

| Enhanced Operational Safety | Creating a safer environment for both workers and passengers, reducing potential liability and promoting a positive reputation. |

| Improved Network Capacity | Minimizing disruptions and slowdowns, allowing for more efficient use of the railway network and potentially increasing traffic volume. |

12. Regulations and Standards for Geo Car Operations

Geo car operations are subject to a variety of regulations and standards, designed to ensure the safety and reliability of railway infrastructure. Railway organizations must comply with these regulations and standards to avoid penalties and legal issues. Understanding the regulatory landscape is essential for successful implementation and operation of geo car technology.

- Federal Railroad Administration (FRA): In the United States, the FRA is the primary regulatory agency for the railway industry. The FRA sets standards for track safety, equipment maintenance, and operating practices. Railway organizations must comply with the FRA’s regulations to ensure the safety of their operations.

- European Union Agency for Railways (ERA): In the European Union, the ERA is responsible for setting standards for railway safety and interoperability. The ERA’s regulations cover a wide range of topics, including track geometry, rail quality, and signaling systems.

- International Organization for Standardization (ISO): ISO is an international organization that develops voluntary standards for a wide range of industries. ISO standards are not legally binding, but they are widely recognized and respected. Railway organizations often use ISO standards to demonstrate their commitment to quality and safety.

- American Railway Engineering and Maintenance-of-Way Association (AREMA): AREMA is a professional organization that develops standards and recommended practices for railway engineering and maintenance. AREMA standards are widely used in North America and are often referenced in regulatory requirements.

These are just a few of the many regulations and standards that apply to geo car operations. Railway organizations must stay up-to-date on the latest regulations and standards to ensure that their operations are in compliance. Failure to comply with regulations and standards can result in penalties, legal issues, and reputational damage.

13. Overcoming Challenges in Geo Car Implementation

Implementing geo car technology can present a variety of challenges for railway organizations. These challenges can range from technical issues to organizational barriers, and addressing them effectively is essential for successful implementation. By anticipating and overcoming these challenges, railway organizations can maximize the benefits of geo car technology and achieve their desired outcomes.

- Technical Challenges: Technical challenges can include issues such as data accuracy, sensor reliability, and system integration. Ensuring that geo car systems provide accurate and reliable data requires careful calibration and maintenance. Integrating geo car systems with existing railway systems can also be challenging, requiring careful planning and coordination.

- Organizational Challenges: Organizational challenges can include resistance to change, lack of training, and poor communication. Implementing geo car technology often requires changes in work processes and organizational structures. Overcoming resistance to change requires effective communication and training.

- Data Management Challenges: Geo cars generate large volumes of data, which must be managed effectively. Data management challenges can include issues such as data storage, data security, and data analysis. Railway organizations need to establish data management protocols that ensure data quality, security, and accessibility.

- Cost Challenges: Implementing geo car technology involves significant upfront costs. Cost challenges can include issues such as equipment procurement, installation, and training. Railway organizations need to conduct a cost-benefit analysis to determine whether the investment is justified.

To overcome these challenges, railway organizations need to adopt a proactive and strategic approach to implementation. This includes conducting thorough planning, providing adequate training, establishing clear communication channels, and investing in appropriate technology and infrastructure. By addressing these challenges effectively, railway organizations can maximize the benefits of geo car technology and achieve their desired outcomes. For expert advice and solutions to these challenges, visit cars.edu.vn.

14. Geo Car Maintenance and Calibration Best Practices

Proper maintenance and calibration are essential for ensuring the accuracy and reliability of geo car systems. Geo cars are complex vehicles equipped with sophisticated sensors and systems, and they require regular maintenance to operate at peak performance. Following best practices for maintenance and calibration can help railway organizations maximize the benefits of geo car technology and ensure the safety and reliability of their operations.

- Regular Inspections: Geo cars should be inspected regularly to identify any potential problems or issues. Inspections should include a thorough examination of the vehicle’s mechanical components, sensors, and systems.

- Sensor Calibration: Geo car sensors should be calibrated regularly to ensure that they are providing accurate and reliable data. Calibration procedures should be performed according to the manufacturer’s recommendations.

- Software Updates: Geo car software should be updated regularly to ensure that it is functioning properly and that it is compatible with other railway systems. Software updates can also include new features and improvements that enhance the performance of geo car systems.

- Data Validation: Geo car data should be validated regularly to ensure that it is accurate and reliable. Data validation procedures can include comparing geo car data with data from other sources, such as track inspection reports and maintenance records.

- Preventive Maintenance: Geo cars should undergo preventive maintenance on a regular basis to prevent potential problems and extend the lifespan of the vehicle. Preventive maintenance can include tasks such as lubricating mechanical components, replacing worn parts, and cleaning sensors.

- Documentation: All maintenance and calibration activities should be documented thoroughly. Documentation should include information such as the date of the activity, the name of the person who performed the activity, and any findings or observations.

15. Training and Certification Programs for Geo Car Operators

Operating geo cars requires specialized skills and knowledge. Geo car operators must be trained to operate the vehicles safely and effectively, interpret the data they collect, and make informed decisions based on that data. Training and certification programs are essential for ensuring that geo car operators have the skills and knowledge they need to perform their jobs competently.

- Geo Car Operation: Training programs should cover the basics of geo car operation, including vehicle operation, sensor operation, and data collection procedures.

- Data Interpretation: Training programs should cover the basics of data interpretation, including how to read and interpret geo car data, how to identify potential problems, and how to make informed decisions based on the data.

- Safety Procedures: Training programs should cover safety procedures, including how to operate geo cars safely, how to respond to emergencies, and how to comply with regulatory requirements.

- Maintenance and Calibration: Training programs should cover maintenance and calibration procedures, including how to perform basic maintenance tasks, how to calibrate geo car sensors, and how to troubleshoot common problems.

- Certification: Geo car operators should be certified to demonstrate that they have the skills and knowledge they need to perform their jobs competently. Certification programs should be accredited by a reputable organization, such as a professional society or a regulatory agency.

16. Geo Cars and Sustainability: Environmental Benefits

Geo cars not only enhance railway safety and efficiency but also contribute to sustainability by reducing the environmental impact of railway operations. By optimizing maintenance practices, reducing energy consumption, and minimizing waste, geo cars help railway organizations operate in a more environmentally responsible manner.

- Reduced Energy Consumption: Geo cars help to reduce energy consumption by ensuring that tracks are well-maintained. Well-maintained tracks reduce rolling resistance, which can significantly impact fuel consumption. By ensuring that tracks are in good condition, geo cars help trains to operate more efficiently, reducing energy costs and minimizing greenhouse gas emissions.

- Reduced Waste: Geo cars help to reduce waste by enabling proactive maintenance. By identifying and addressing defects early, geo cars help to prevent further damage and deterioration, reducing the need for costly replacements and upgrades. This reduces the amount of waste generated by railway operations.

- Optimized Maintenance Practices: Geo cars help to optimize maintenance practices by providing detailed information on track conditions. This information allows maintenance teams to prioritize their efforts, focusing on areas that require immediate attention. By targeting maintenance activities to specific locations, railway organizations can reduce the amount of time and resources spent on unnecessary inspections and repairs, minimizing the environmental impact of maintenance activities.

- Environmental Monitoring: Geo cars can be equipped with sensors to monitor environmental conditions along railway tracks. These sensors can measure air quality, noise levels, and other environmental parameters. This information can be used to assess the environmental impact of railway operations and identify opportunities for improvement.

17. Case Studies: Successful Geo Car Implementations

Examining successful geo car implementations provides valuable insights into best practices, challenges, and outcomes. These case studies demonstrate how different railway organizations have leveraged geo car technology to improve safety, efficiency, and sustainability. By studying these examples, railway organizations can learn from the experiences of others and develop effective implementation strategies.

- Case Study 1: BNSF Railway

BNSF Railway has successfully implemented geo car technology across its 32,500-mile network. BNSF’s geo car fleet includes both manned and unmanned vehicles, equipped with a variety of sensors and systems. BNSF has used geo cars to improve track safety, reduce downtime, and optimize resource allocation. The implementation of the Track Health Optical Recognition (THOR) system has been particularly successful, enabling proactive maintenance and preventing rail breaks.

- Case Study 2: Network Rail (UK)

Network Rail has successfully implemented geo car technology to monitor track conditions and identify potential hazards across its network. Network Rail’s geo car fleet includes a variety of vehicles, equipped with different types of sensors and systems. Network Rail has used geo cars to improve track safety, reduce downtime, and optimize vegetation management.

- Case Study 3: Queensland Rail (Australia)

Queensland Rail has successfully implemented geo car technology to inspect its 6,600-kilometer network. Queensland Rail’s geo car fleet includes a variety of vehicles, equipped with high-resolution cameras, laser measurement systems, and other sensors. Queensland Rail has used geo cars to improve track safety, reduce downtime, and optimize maintenance practices.

18. Geo Cars and Predictive Maintenance Strategies

Geo cars play a crucial role in predictive maintenance strategies, enabling railway organizations to anticipate