Cable cars, a beloved symbol of San Francisco, are unique vehicles that move without an engine or motor onboard. Unlike typical automobiles or even electric streetcars, their power source is centralized, residing in a dedicated powerhouse. This intriguing system begs the question: how do cable cars actually work? Let’s delve into the fascinating mechanics that drive these historical vehicles.

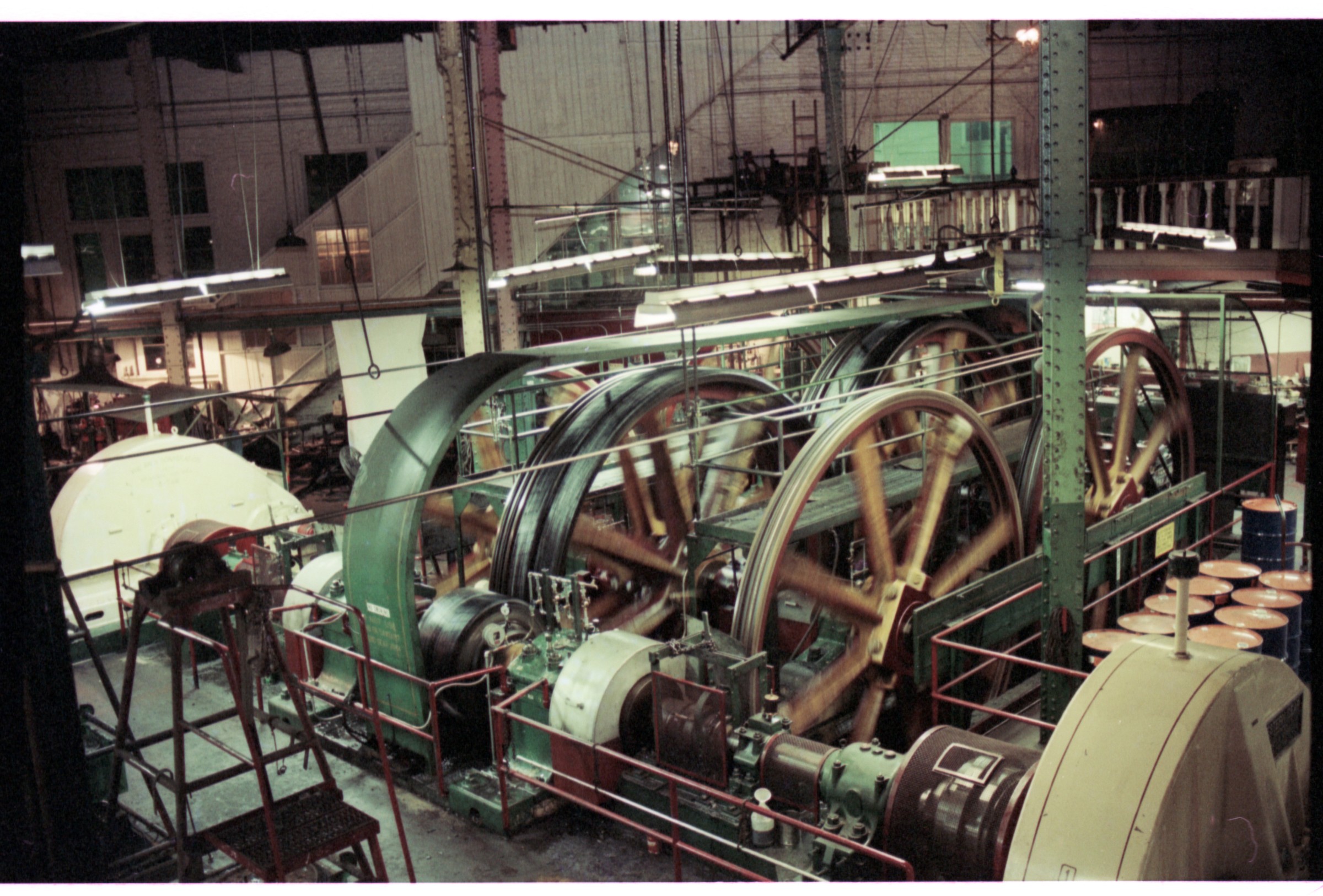

The heart of the cable car system lies in the powerhouse, specifically located at Washington and Mason Streets, which also houses the Cable Car Museum. Here, powerful electric motors, evolving from original steam-powered engines, drive massive winding wheels. These wheels are the engine room of the entire operation, responsible for propelling the cables that run beneath the city streets. These cables are situated in a trench, directly under the slot that runs between the cable car tracks – the very slot you see in the pavement.

Interestingly, San Francisco’s cable car network utilizes four distinct cables. One cable powers the California line, another serves the Powell Street line, and two additional cables cater to the outer sections of the two Powell lines, specifically Mason and Hyde. Each cable operates independently with its own set of winding wheels within the powerhouse. A crucial component of this system is the adjustable rearmost winding wheel in each set. This adjustability is vital for maintaining consistent cable tension. As cables naturally stretch over time with continuous use, maintenance workers periodically adjust this wheel backward to ensure the cable remains taut and operational. These robust cables are over an inch in diameter, constructed from six steel strands, each composed of 19 wires, all wrapped around a sisal rope core for added strength and flexibility.

The Grip: Connecting Car to Cable

Each cable car is equipped with a mechanical grip, or in some cases, two grips as seen in the double-ended California cars. This grip functions similarly to large pliers, providing the crucial link between the car and the continuously moving cable. The operator, known as the gripman (or gripwoman, with two women having held this position in history), controls the car’s movement by manipulating this grip. They can “take rope” – engage the grip with the cable – to start moving or “drop rope” – disengage the grip – to stop. It’s important to note that the cables move at a constant speed of 9.5 miles per hour. Therefore, if a cable car exceeds this speed, it’s undoubtedly traveling downhill, relying on gravity rather than the cable for propulsion, and the grip is not actively engaged.

Taking and Dropping the Rope: Navigating the System

At terminal points and strategic locations throughout the cable car network, you’ll observe mechanisms that facilitate the grip’s engagement and disengagement with the cable. At some terminals, a lever in the street is operated by the conductor. This action physically lifts the cable upwards, making it accessible for the grip to latch onto. Conversely, at other terminals and various points along the routes, dips are intentionally built into the tracks. These dips lower the cable car and its grip down to the level of the cable running beneath the street, allowing the grip to grasp the moving cable.

A particularly noteworthy example of this system in action is at the intersection of the Powell and California cable lines, the world’s only cable car crossing. Following historical precedence, the California line, being the older system established in 1878, holds priority. Consequently, California Street cable cars maintain their grip on the cable as they traverse the Powell Street intersection.

In contrast, Powell Street cable cars must release their grip on the cable before crossing the California Street tracks. This procedure is critical to prevent a potentially hazardous situation. If a Powell cable car were to maintain its grip for too long at this intersection, it could pull the lower Powell cable upwards and into contact with the higher California cable. The Powell car’s grip could then collide with and potentially sever the California Street cable, disrupting the entire system.

To mitigate this risk, a safety system is in place beneath Powell Street on both sides of the California tracks. This system includes an alarm and a mechanism designed to physically force the Powell cable out of the grip if it’s held too long. While effective as a safeguard, this forced release can cause damage to both the cable and the grip, highlighting the importance of precise operation. Fortunately, due to the expertise and skill of the gripmen, such incidents are extremely rare. Observing a Powell gripman approaching this intersection, especially northbound from Market Street, is a testament to their skill. They must ascend the hill firmly gripping the cable, then, while simultaneously ringing the bell to alert crossing vehicles, skillfully release the grip lever at precisely the right moment, allowing the car to coast across the California tracks with a distinctive clatter.

Adding another layer of safety, a control tower situated at the southeast corner of California and Powell Streets is staffed by a Muni employee. This individual uses a light signaling system to manage the flow of cable cars on both lines, ensuring they crest the hill in an organized manner and preventing potential collisions at the intersection.

After a Powell cable car crosses the California tracks, it encounters one of the aforementioned dips in the pavement, enabling it to “take rope” and re-engage with the cable. For Powell cars heading towards Market Street, this re-engagement occurs almost immediately before they descend the steep incline to Pine Street. However, for Powell cars traveling towards Fisherman’s Wharf, the dip in the pavement is located further down the line, more than three blocks away, where the two Powell lines diverge, and each is assigned its own dedicated cable. During these three blocks of gentler downgrade, Powell cars “freewheel,” operating without cable assistance. This freewheeling segment often becomes the fastest part of the journey, as the cable-driven sections are speed-limited to 9.5 miles per hour.

Historically, gripmen on the O’Farrell, Jones, and Hyde Streets line, which opened in 1891, faced a particularly challenging route. As the newest line, its cable was designated “inferior” or lower than older cable lines at every crossing. This meant gripmen on this line had to drop and re-engage the cable a staggering 22 times on each round trip, demanding exceptional skill and focus.

Stopping a Cable Car: Simple Yet Effective Braking Systems

Cable cars utilize a combination of three straightforward braking systems: wheel brakes, track brakes, and an emergency brake. Each wheel is equipped with a soft steel shoe. When activated, these shoes clamp tightly against the wheel, slowing and stopping the car. These wheel brakes are operated by foot pedals, located at both ends of California cars and at the front end of Powell cars, allowing for control from either operating position. Additionally, Powell cars feature rear track brakes, activated by a conductor’s lever on the rear platform.

Track brakes consist of wooden blocks, typically made of soft Monterey Fir, positioned between the wheel sets on each car. Each car has four of these blocks, each two feet long. When the gripman pulls back on the track brake lever, situated near the cable grip lever, these wooden blocks press firmly against the tracks, providing significant additional braking force to help stop the car.

The emergency brake is reserved for critical situations. In the rare event that the standard brakes are insufficient to stop the car, the gripman engages the red emergency brake lever. This action forces a robust 18-inch steel wedge into the center slot between the tracks. The force exerted is so immense that it brings the cable car to an abrupt stop. In fact, the wedge becomes so tightly lodged that specialized cutting equipment, like a cutting torch, is sometimes required to remove it from the slot.

Turning Cable Cars Around: Turntables and Reversing

Single-ended Powell Street cable cars, upon reaching the end of their line, are rotated on large turntables. These turntables are purely mechanical, relying on ball bearings and rollers for smooth operation. The cables themselves do not extend directly into the turntable area. Instead, they reverse direction separately, away from the turntable, wrapping around a large wheel housed in an underground bunker known as a “sheave pit.”

The areas surrounding the turntables are carefully designed to allow gripmen to simply release the brakes and coast the cable car onto the turntable. (The cable grip is already disengaged at this point). Once positioned on the turntable, the gripman engages the car’s brakes, disembarks, and, along with the conductor, manually rotates the car. This rotation is achieved either by pushing on stanchions at each end of the car or by using pipework mounted on the turntables, a feature added in recent decades to facilitate turning without directly touching the cable car.

Historically, until the 1970s, passengers were permitted to assist the crews in turning the cable cars, but this practice is no longer allowed for safety reasons. Similarly, passengers were once able to jump aboard the cable car as it coasted towards the turntable, gaining a free turntable spin and ensuring their preferred seat for the return journey. This practice is also now prohibited, and boarding is strictly managed through a queue system.

California Street cars, in contrast to the Powell Street cars, are designed to operate bidirectionally, eliminating the need for turntables. These cars are built with grips and brakes at both ends. At the end of the line, the gripman simply operates the car through a switch, applies the brakes, and then swaps positions with the conductor. The cable car then proceeds in the opposite direction. The switch at the terminal is spring-loaded to ensure it remains aligned with the departure track, preventing potential derailments and ensuring smooth transitions for the cable cars.

In conclusion, the operation of cable cars is a fascinating blend of centralized power, mechanical grips, and ingenious braking and turning systems. These iconic vehicles, devoid of onboard engines, rely on a continuous loop of underground cables powered from a central powerhouse, showcasing a remarkable feat of engineering that continues to captivate and transport people in San Francisco.