For many drivers, car air conditioning is a must-have, especially during scorching summer days. While the relief it provides is widely appreciated, the inner workings of this system often remain a mystery. Instead of simply enjoying the cool air, have you ever wondered, “How Does Car Air Conditioning Work?”

The magic behind your car’s AC lies in a clever process of manipulating refrigerant, a special substance that transitions between liquid and gaseous states. This transition is key to absorbing heat and humidity from inside your car, ultimately blowing out refreshing, dry, and cool air. Modern automotive AC systems have evolved, with refrigerants shifting from the ozone-damaging R-12 (Freon) to R-134a, and now increasingly towards the more environmentally friendly R-1234yf.

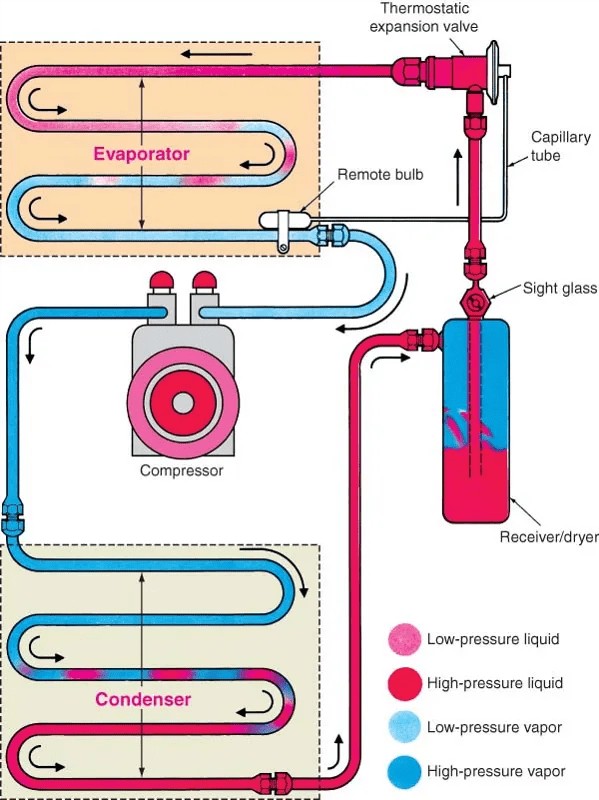

A car AC system is composed of several crucial parts, each playing a vital role in the cooling cycle. These include the compressor, condenser, dryer, metering device, and evaporator. Understanding these components and their functions is the first step to appreciating the ingenuity of automotive air conditioning. Common issues, like refrigerant leaks or blockages in airflow to the condenser, can compromise the system’s efficiency. Automotive technicians specializing in AC systems are in high demand to diagnose and rectify these problems, making it a specialized and valuable skill in the automotive industry.

If you’re keen to understand the science behind staying cool on the road, delve deeper into the theory, components, and operation of car AC systems in the sections below.

The Science of Cool Air: How Car AC Works

The fundamental principle behind car AC operation is the manipulation of refrigerant between liquid and gaseous states. This process is not just a simple change of state; it’s a carefully orchestrated cycle that leverages the laws of thermodynamics to extract heat from your car’s cabin.

To facilitate this state change in the refrigerant, the AC system meticulously controls both pressure and temperature. By cycling the refrigerant through different components under varying pressure and temperature conditions, the system effectively absorbs heat and releases it outside the vehicle, leaving you with a comfortably cool interior.

Refrigerants: The Cooling Agents of Car AC Systems

The type of refrigerant used in car AC systems has seen significant changes over the years, primarily driven by environmental concerns.

Initially, R-12, commonly known as Freon, was the industry standard. Freon was favored for its effectiveness as a CFC (chlorofluorocarbon) refrigerant. It was non-flammable and non-toxic to humans, making it seemingly ideal. However, in the late 1980s, scientific research revealed the detrimental impact of R-12 on the Earth’s ozone layer, leading to a global effort to phase it out.

In the mid-1990s, automotive manufacturers transitioned to R-134a. This refrigerant is an HFC (hydrofluorocarbon) and importantly, it does not deplete the ozone layer like Freon. However, R-134a is still a potent greenhouse gas, contributing to climate change, which spurred the search for even more eco-friendly alternatives.

The latest generation of refrigerant is R-1234yf. This HFO (hydrofluoroolefin) refrigerant significantly reduces greenhouse gas emissions compared to R-134a. Europe has mandated the use of R-1234yf, and it is increasingly becoming the new standard in the United States and globally as environmental regulations tighten.

If your car’s AC performance declines, a common solution is to “recharge” the system. This process involves a qualified technician adding new refrigerant to the system, ensuring it has the optimal charge to function efficiently.

Key Components of a Car AC System

A car’s air conditioning system is an intricate network of parts working in harmony. Understanding each component’s function is crucial to grasping the overall system operation.

Compressor: The Heart of the System

- The compressor is essentially the power unit of the entire AC system. It acts as a pump, creating a pressure difference that drives the refrigerant flow. It’s the component that separates the low-pressure side from the high-pressure side of the system.

- Its primary function is to take in low-pressure, low-temperature refrigerant gas and compress it into a high-temperature, high-pressure gas. This compression is what raises the refrigerant’s temperature significantly.

- Typically, the compressor is mounted at the front of the engine and is powered by the serpentine belt, drawing mechanical energy from the engine to perform its compression work.

Condenser: Releasing Heat

- The condenser’s role is to cool down the high-pressure, high-temperature refrigerant gas discharged from the compressor. While maintaining the high pressure, it facilitates heat rejection from the refrigerant to the outside air.

- As the refrigerant cools within the condenser, it undergoes a phase change from a gaseous state to a high-pressure liquid state. This condensation process releases heat that was absorbed earlier in the cycle.

- Similar in appearance and function to an engine radiator, the condenser uses forced air – either from an electric fan or airflow generated by vehicle movement – to dissipate heat.

- It’s strategically positioned at the front of the vehicle, usually in front of the engine radiator and behind the grill, to maximize exposure to airflow for efficient heat transfer.

Dryer (or Receiver-Dryer): Removing Moisture and Filtering

- The dryer, also known as a receiver-dryer, is crucial for removing moisture from the refrigerant. Moisture in the AC system can lead to corrosion and reduced system efficiency. It utilizes a desiccant, a drying agent, to absorb any water present in the refrigerant.

- Beyond moisture removal, the dryer also has a filtering function, trapping any solid contaminants that might be circulating in the system. This helps to protect other components from damage and ensures system cleanliness.

- The dryer is located on the high-pressure side of the system, typically positioned between the condenser and the metering device, ensuring the refrigerant is dry and clean before it proceeds further into the cooling cycle.

Metering Device: Controlling Refrigerant Flow and Pressure Drop

- The metering device is responsible for controlling the flow of refrigerant into the evaporator and, more importantly, for reducing the pressure of the liquid refrigerant. This pressure reduction is critical for the next stage of the cooling process.

- Two common types of metering devices are used: the expansion valve and the fixed orifice tube. Both achieve the same outcome – a pressure drop – but through slightly different mechanisms.

- As the high-pressure liquid refrigerant passes through the metering device, its pressure is significantly reduced. This pressure drop causes a rapid decrease in the refrigerant’s temperature.

- After exiting the metering device, the refrigerant remains in a liquid state but is now at a much lower temperature and pressure, ready to enter the evaporator. It’s located on the high-pressure side, typically between the dryer and the firewall, near the entrance to the passenger compartment.

Evaporator: Cooling the Cabin Air

- The evaporator is where the actual cooling of the cabin air takes place. In the evaporator, the low-pressure, low-temperature liquid refrigerant absorbs heat from the air passing over it.

- As it absorbs heat, the refrigerant undergoes another phase change, this time from a liquid back to a gaseous state. This evaporation process is what produces the cooling effect. Think of it like how evaporating sweat cools your skin.

- Cabin air is blown across the evaporator’s fins by the blower fan. As the air passes over the cold evaporator, heat is transferred from the air to the refrigerant, cooling and drying the air in the process. Moisture in the air condenses on the cold evaporator coils and is drained out of the vehicle.

- Uniquely, the evaporator is the only AC component located inside the passenger compartment, typically situated behind the dashboard. This strategic placement allows it to directly cool the air that is circulated within the car.

Refrigerant’s Journey: A Cycle of Cooling

To summarize the refrigerant’s path and its state changes throughout the AC system:

- Entry to Compressor: Refrigerant enters the compressor as a low-temperature, low-pressure gas.

- Exit from Compressor: It leaves the compressor as a high-temperature, high-pressure gas.

- Condenser Stage: In the condenser, the refrigerant cools down and changes into a high-pressure liquid.

- Dryer Stage: The refrigerant, still at high pressure, passes through the receiver/dryer where moisture is removed.

- Metering Device Stage: The expansion valve or orifice tube reduces the refrigerant’s pressure significantly.

- Evaporator Stage: Refrigerant enters the evaporator as a low-pressure liquid. Here, it absorbs heat from the cabin air and converts back into a low-pressure gas, causing a cooling effect. The cooled and dehumidified air is then blown into the car.

- Cycle Repeats: The low-pressure gas refrigerant then returns to the compressor, and the cycle begins again.

This continuous cycle of compression, condensation, expansion, and evaporation is what allows your car’s AC system to consistently produce cool air.

Car AC System Diagram

For a visual representation of these components and their connections, refer to the diagram below:

Car AC System Diagram

Car AC System Diagram

Common Car AC System Problems

Car AC systems, operating under pressure, rely on being hermetically sealed. Any breach that allows refrigerant leakage or contaminant entry can lead to system malfunctions.

A refrigerant leak, wherever it occurs, will undermine the system’s ability to cool effectively. Simply adding more refrigerant without addressing the leak is only a short-term fix. The correct approach is to pinpoint the source of the leak, replace the faulty component (like a hose, seal, or component itself), and then properly evacuate and recharge the system.

Beyond just reducing cooling capacity, refrigerant leaks can also damage the compressor. If the system is low on refrigerant due to a leak, the compressor may overheat and suffer internal damage as it works harder to try and achieve the desired pressure and cooling. Compressor replacement is often a significant expense as they are typically not serviceable as individual parts.

Another common issue is reduced airflow through the condenser. The condenser, being at the front of the vehicle, is susceptible to blockage from road debris, leaves, dirt, and bugs accumulating on its fins. This blockage restricts airflow, reducing the condenser’s ability to dissipate heat effectively, leading to diminished AC performance. Regular cleaning of the condenser fins can help maintain optimal airflow and system efficiency.

Car AC Systems and Your Automotive Career

Air conditioning is no longer a luxury; it’s a standard feature in almost every new vehicle sold today. This widespread adoption means that automotive technicians who are skilled in diagnosing and repairing AC systems are consistently in demand. Both dealerships and independent repair shops regularly require technicians capable of handling AC issues.

Customers often present a range of AC-related complaints, from simply “it’s blowing warm air” to more specific issues like “there are loud noises when the AC is on” or even “water is leaking inside the car.” These scenarios highlight the diverse problems that can arise in AC systems and the need for skilled technicians to address them.

Frequently Asked Questions About Car AC Systems

How does a car air conditioner actually cool the air?

Car AC systems cool air using the vehicle’s compressor to increase the pressure and temperature of the refrigerant. This high-pressure refrigerant then releases heat in the condenser, becomes a liquid, and then its pressure is dropped before entering the evaporator. In the evaporator, the refrigerant turns back into a gas, absorbing heat from the cabin air in the process, thus cooling the air. The receiver-dryer removes moisture and contaminants to keep the system clean and efficient.

What are the primary parts of a car’s AC system?

The main components are:

- Compressor

- Condenser

- Evaporator

- Receiver-dryer (or Dryer)

- Expansion valve (or Metering Device)

How does refrigerant cause cooling in a car AC?

The cooling effect is created in the evaporator. As refrigerant passes through the evaporator and changes from a liquid to a gas, it absorbs heat from the surrounding air. Air is forced across the evaporator, and the refrigerant draws heat from this air during its phase change. Consequently, the air exiting the evaporator is cooler and drier than the air that entered.

Pursue a Career as an Automotive Technician

Is a career as an automotive technician, specializing in systems like AC, something that interests you? At institutions like Universal Technical Institute (UTI), students receive comprehensive training on all vehicle systems, including advanced air conditioning.

In a relatively short period, you can acquire the hands-on skills and theoretical knowledge necessary to start an entry-level career in the automotive field.[^1],[^2] For more information about UTI’s programs, explore their automotive program page and request information to connect with an Admissions Representative.

UTI Campuses Offering Automotive Technician Training

Start Your Mechanic or Technician Career Today

- Hands-on training: Gain practical experience with equipment from leading industry brands.

- Flexible start dates: Classes begin every 3-6 weeks, allowing you to start your training without delay.

- No commitment pressure: Get all your questions answered without any obligation.

Related Articles

How Long Does It Take to Become an Automotive Mechanic?

What Is an Automotive Service Writer and What Do They Do?

The Automotive Technician Shortage: What Does This Mean for Your Career?

[^1]: UTI is an educational institution and cannot guarantee employment or salary.

[^2]: For program outcome information and other disclosures, visit www.uti.edu/disclosures.

Universal Technical Institute of Illinois, Inc. is approved by the Division of Private Business and Vocational Schools of the Illinois Board of Higher Education.