It’s a common summer scenario: you jump into your car, turn the ignition, and immediately crank the AC to escape the sweltering heat. While most drivers appreciate the cool air blowing from the vents, few understand the intricate process behind it. Many might jokingly say, “I don’t need to know how it works, as long as it works!”, but understanding your car’s air conditioning system can be beneficial for maintenance and troubleshooting.

Car air conditioning systems are marvels of engineering that utilize the principles of thermodynamics to keep your cabin comfortable. They operate by cycling refrigerant, a special substance, between liquid and gaseous states. This process allows the system to absorb heat and humidity from inside your car and expel it outside, delivering cool, dry air in return. Over the years, the refrigerants used in these systems have evolved, moving from the ozone-depleting R-12 (Freon) to R-134a, and now increasingly towards R-1234yf, a more environmentally friendly option with a lower global warming potential.

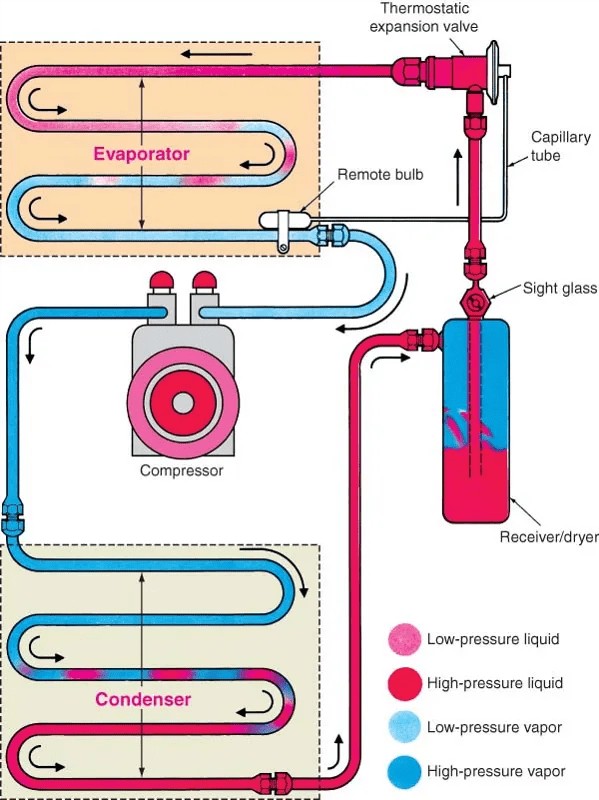

To truly grasp “How Does The A/c System Work In A Car?”, we need to delve into its key components and their functions. Let’s explore the compressor, condenser, dryer, metering device, and evaporator – the unsung heroes working tirelessly to keep you cool on your drives. Understanding these parts and how they interact will not only satisfy your curiosity but also empower you to recognize potential issues and communicate effectively with automotive technicians.

Understanding the Core Components of Your Car’s AC System

The car AC system is a closed-loop system, meaning the refrigerant continuously circulates through its components. Each component plays a vital role in the cooling process. Let’s break down each part:

The Compressor: The Heart of the System

The compressor is often considered the “heart” of the AC system. Its primary function is to pressurize and circulate the refrigerant throughout the system. Located at the front of the engine and driven by the serpentine belt, the compressor takes in low-pressure, gaseous refrigerant and compresses it into a high-temperature, high-pressure gas. This compression process is essential because it raises the refrigerant’s temperature above the outside air temperature, allowing heat to be effectively expelled later in the cycle. Without a functioning compressor, the entire AC system would fail to operate.

The Condenser: Releasing Heat

The condenser’s job is to cool down the high-pressure, high-temperature refrigerant gas coming from the compressor. Resembling a miniature radiator, the condenser is typically positioned at the front of the vehicle, near the engine radiator. As outside air flows across the condenser, often aided by the radiator fan and vehicle movement, it draws heat away from the refrigerant. This heat exchange causes the refrigerant to transition from a high-pressure gas to a high-pressure liquid. Think of the condenser as the component that releases the heat extracted from your car’s interior to the outside environment.

The Dryer or Receiver-Drier: Removing Moisture and Contaminants

The dryer, also known as the receiver-drier, is a crucial component for maintaining the longevity and efficiency of the AC system. Its primary function is to remove moisture and contaminants, such as debris and acids, from the refrigerant. Moisture in the system can react with the refrigerant and oil, creating harmful acids that can corrode internal components and reduce cooling efficiency. The dryer contains a desiccant, a drying agent, that absorbs moisture. It also acts as a filter, trapping any solid particles that might be circulating within the system. Located on the high-pressure side, usually between the condenser and the metering device, the dryer ensures that only clean, dry refrigerant reaches the expansion valve or orifice tube.

The Metering Device: Controlling Refrigerant Flow and Pressure Drop

The metering device is responsible for controlling the flow of refrigerant into the evaporator and creating a pressure drop, which is essential for the cooling process. There are two main types of metering devices used in car AC systems: the expansion valve and the orifice tube. Both devices achieve the same goal: they restrict the flow of high-pressure liquid refrigerant, causing a pressure drop. This pressure reduction allows the refrigerant to expand and vaporize in the evaporator, a process that absorbs heat. The metering device is strategically placed on the high-pressure side, between the dryer and the evaporator, often near the firewall of the vehicle.

The Evaporator: Where Cooling Happens

The evaporator is where the actual cooling of the air takes place. Positioned inside the passenger compartment, typically behind the dashboard, the evaporator resembles another small radiator. Low-pressure liquid refrigerant from the metering device enters the evaporator. As warm cabin air is blown across the evaporator’s fins by the blower fan, heat from the air is absorbed by the refrigerant, causing the refrigerant to vaporize and turn into a low-pressure gas. This heat absorption process is what cools the air. The cooled, dehumidified air is then circulated back into the cabin through the vents, providing you with that refreshing relief from the heat. The evaporator also plays a role in dehumidification, as moisture from the air condenses on its cold surface and is drained out of the vehicle.

Diagram of a car air conditioning system showing compressor, condenser, dryer, metering device, and evaporator and refrigerant flow.

Diagram of a car air conditioning system showing compressor, condenser, dryer, metering device, and evaporator and refrigerant flow.

The Refrigerant Cycle: A Step-by-Step Journey

To further understand “how does the a/c system work in a car?”, let’s trace the journey of the refrigerant through the entire system:

-

Entering the Compressor (Low-Pressure Gas): The cycle begins with low-temperature, low-pressure refrigerant in a gaseous state entering the compressor.

-

Leaving the Compressor (High-Temperature, High-Pressure Gas): The compressor pressurizes the refrigerant, converting it into a high-temperature, high-pressure gas.

-

Condensation in the Condenser (High-Pressure Liquid): The hot, high-pressure gas flows into the condenser where it cools down and changes state to a high-pressure liquid, releasing heat to the outside air.

-

Filtration and Drying in the Dryer (High-Pressure Liquid): The high-pressure liquid refrigerant then passes through the dryer, where moisture and contaminants are removed.

-

Pressure Drop at the Metering Device (Low-Pressure Liquid): The refrigerant reaches the metering device (expansion valve or orifice tube), which restricts flow and causes a significant pressure drop. The refrigerant is now a low-pressure liquid, ready to evaporate.

-

Evaporation in the Evaporator (Low-Pressure Gas, Cooling Effect): The low-pressure liquid refrigerant enters the evaporator. Here, it absorbs heat from the cabin air as it changes back into a gaseous state. This process cools the air that is blown into the car.

-

Back to the Compressor (Low-Pressure Gas): The low-pressure, gaseous refrigerant then returns to the compressor to begin the cycle anew.

This continuous cycle of compression, condensation, expansion, and evaporation is what allows your car’s AC system to effectively cool the cabin.

Common AC System Problems and Maintenance

Like any mechanical system, car ACs can experience issues. Understanding common problems can help you address them promptly and prevent costly repairs.

Refrigerant Leaks: Because the AC system operates under pressure, it relies on being completely sealed. Leaks are a common problem and can occur in hoses, seals, or components. A leak not only reduces cooling efficiency but can also damage the compressor due to lack of lubrication. If your AC is blowing warm air, a refrigerant leak is a prime suspect. Diagnosing and repairing leaks often requires specialized equipment and expertise.

Compressor Failure: The compressor is a complex mechanical component and can fail due to various reasons, including lack of lubrication from refrigerant leaks, internal wear and tear, or electrical issues. A failed compressor is a significant repair, often requiring replacement of the entire unit.

Condenser Blockage: The condenser, being located at the front of the car, is vulnerable to blockage from road debris, dirt, and bugs. Reduced airflow through the condenser hinders its ability to dissipate heat effectively, leading to decreased AC performance. Regular cleaning of the condenser fins can help prevent this issue.

Dryer Saturation: Over time, the desiccant in the dryer can become saturated with moisture, reducing its effectiveness. A saturated dryer can no longer remove moisture, potentially leading to system corrosion and component damage. The dryer is typically replaced periodically as part of routine AC maintenance.

Electrical Issues: The AC system relies on various electrical components, including relays, switches, and sensors. Electrical problems can disrupt the system’s operation and prevent components like the compressor clutch or blower fan from engaging.

Regular AC Service: While car AC systems are designed to be relatively low-maintenance, periodic checks and servicing can prolong their lifespan and maintain optimal performance. This may include refrigerant checks, leak detection, system cleaning, and component inspections. Consulting your vehicle’s service manual and a qualified automotive technician for recommended maintenance schedules is advisable.

The Importance of AC Systems and Automotive Technicians

In today’s vehicles, air conditioning is no longer a luxury but a standard feature. This widespread adoption means that automotive technicians skilled in AC system diagnosis and repair are in high demand. Technicians play a crucial role in keeping drivers comfortable and safe, especially in hot climates. They are equipped with specialized tools and knowledge to troubleshoot complex AC issues, from refrigerant leaks to compressor failures and electrical malfunctions.

For those considering a career in the automotive industry, mastering AC system repair is a valuable skill. Automotive technology programs, like those offered at Universal Technical Institute (UTI), provide comprehensive training in all aspects of vehicle systems, including advanced air conditioning systems. These programs equip aspiring technicians with the hands-on experience and theoretical knowledge needed to excel in this essential area of automotive service.

Frequently Asked Questions About Car AC Systems

How often should I recharge my car AC?

Unless there is a leak in the system, a car AC should not need frequent recharging. If you find yourself needing to recharge your AC system regularly, it indicates a likely leak that needs to be addressed by a technician. Simply recharging a leaking system is a temporary fix and can lead to further problems and environmental concerns.

Is it normal for water to drip from my car after using the AC?

Yes, it is perfectly normal for water to drip from underneath your car after using the AC. This water is condensation that forms on the evaporator as it cools and dehumidifies the air. The moisture is collected and drained out of the vehicle. This is a sign that your AC system’s dehumidification function is working correctly.

Can I recharge my car AC myself?

While DIY AC recharge kits are available, it’s generally recommended to have your AC system serviced by a qualified technician. Improper recharging can lead to overcharging or undercharging, both of which can damage the system. Furthermore, if there is a leak, simply adding refrigerant will not solve the underlying problem. Technicians have the equipment to properly diagnose issues, identify leaks, and recharge the system correctly, ensuring optimal performance and longevity.

Understanding “how does the a/c system work in a car” not only satisfies curiosity but also empowers car owners to better understand their vehicles and communicate effectively with automotive professionals. The next time you enjoy the cool air in your car, you’ll have a deeper appreciation for the intricate system working behind the scenes to keep you comfortable on your journey.