When summer hits, a functioning car air conditioning (AC) system is no longer a luxury—it’s a necessity. You might often hear people say, “I don’t need to know how it works, I just need it to work!” But understanding How Does The Ac Work In A Car can actually help you appreciate this essential system and even troubleshoot minor issues.

Car AC systems are ingenious devices that use basic principles of physics to keep your car cabin cool and comfortable. They work by cycling refrigerant, a special substance, between liquid and gaseous states. This process absorbs heat and humidity from inside your vehicle, releasing cool, dry air in its place. Initially, car ACs used R-12 (Freon), but due to environmental concerns, the industry shifted to R-134a and now increasingly to R-1234yf, a refrigerant with a lower global warming potential.

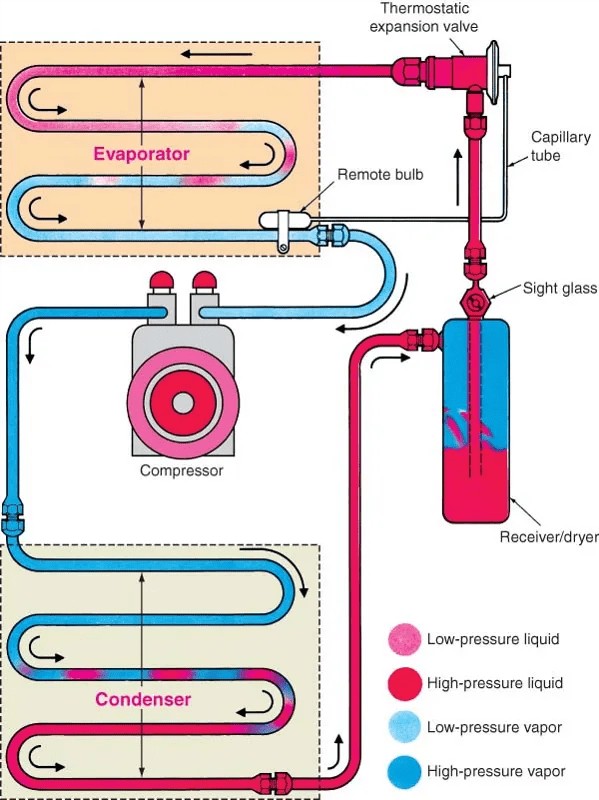

The car AC system is composed of several key components, each playing a vital role in the cooling process. These include the compressor, condenser, receiver-drier, expansion valve or orifice tube (metering device), and evaporator. Common problems, such as refrigerant leaks or blockages in airflow to the condenser, can hinder the system’s efficiency. Professionals specializing in automotive AC repair are crucial for diagnosing and fixing these issues, making it a specialized and in-demand skill within automotive technology.

If you’ve ever wondered about the mechanics behind your car’s cool air, keep reading to delve deeper into the principles, parts, and operation of your car’s AC system.

The Science Behind How Car AC Works

The core principle of how car AC works lies in the manipulation of refrigerant between liquid and gas. This phase change is not just a physical transformation; it’s the key to heat transfer. When a liquid turns into a gas (evaporation), it absorbs heat from its surroundings. Conversely, when a gas turns into a liquid (condensation), it releases heat. Car AC systems exploit these properties to move heat out of your car.

To control these state changes, the AC system meticulously manages the refrigerant’s pressure and temperature. By increasing pressure, the refrigerant can be condensed into a liquid and release heat outside the cabin. By decreasing pressure, the liquid refrigerant can evaporate and absorb heat from inside the cabin. This cycle, repeated continuously, is what keeps your car interior refreshingly cool.

Types of Refrigerants Used in Car AC Systems

The journey of refrigerants in car AC systems reflects a growing awareness of environmental impact.

-

R-12 (Freon): Initially, R-12, commonly known as Freon, was the industry standard. This CFC (chlorofluorocarbon) based refrigerant was highly effective, non-flammable, and relatively non-toxic to humans. However, in the late 1980s, its detrimental effect on the Earth’s ozone layer became apparent, leading to its phase-out.

-

R-134a: In the mid-1990s, automakers transitioned to R-134a. This HFC (hydrofluorocarbon) refrigerant addressed the ozone depletion issue of R-12. While better for the ozone layer, R-134a still has a significant global warming potential, prompting the search for even more environmentally friendly alternatives.

-

R-1234yf: The latest generation refrigerant is R-1234yf. This HFO (hydrofluoroolefin) refrigerant significantly reduces greenhouse gas emissions compared to R-134a. Europe has already mandated its use, and it is increasingly becoming the standard in the United States and globally, reflecting a commitment to reducing the environmental footprint of car AC systems.

If your car’s AC performance declines, a certified technician can “recharge” the system by adding new refrigerant. However, simply recharging a system with a leak is a temporary fix; addressing the underlying leak is crucial for a lasting solution.

Key Components of a Car AC System and Their Functions

Understanding how does the AC work in a car also involves knowing the role of each component in the system:

Compressor

The compressor is the heart of the AC system. Think of it as the pump that circulates refrigerant throughout the system. Its primary function is to:

- Separate the high-pressure and low-pressure sides: Creating the pressure difference necessary for the refrigerant cycle.

- Compress low-pressure, low-temperature gas into high-pressure, high-temperature gas: This compression process is essential for raising the refrigerant’s temperature so it can release heat in the condenser.

- Mechanical Operation: The compressor is typically belt-driven, connected to the engine’s serpentine belt, drawing power from the engine to operate. It’s usually mounted at the front of the engine.

Condenser

The condenser’s job is to cool down the high-pressure, high-temperature refrigerant gas coming from the compressor. It functions similarly to a radiator in your engine’s cooling system:

- Heat Rejection: As hot refrigerant passes through the condenser coils, air flows across it (either from the engine fan or vehicle movement), carrying heat away from the refrigerant.

- Phase Change: As the refrigerant cools, it transitions from a high-pressure gas to a high-pressure liquid. This condensation process releases the heat absorbed earlier in the evaporator.

- Location: The condenser is usually positioned at the front of the vehicle, behind the grille, to maximize airflow for efficient heat dissipation.

Receiver-Drier (or Accumulator in some systems)

The receiver-drier (or accumulator in some systems, though receiver-drier is more common with expansion valves) plays a critical role in ensuring refrigerant purity and system longevity:

- Moisture Removal: It contains a desiccant, a drying agent, that absorbs any moisture that may have entered the system. Water contamination can lead to ice formation, which can block refrigerant flow and damage components.

- Filtering Debris: It also acts as a filter, removing any solid contaminants that might circulate within the system, protecting sensitive components like the expansion valve or orifice tube.

- Refrigerant Reservoir: In some systems, it also serves as a temporary storage for liquid refrigerant, ensuring a consistent supply to the expansion valve.

- Location: It’s located on the high-pressure side of the system, typically between the condenser and the expansion valve.

Metering Device: Expansion Valve or Orifice Tube

The metering device, which can be either an expansion valve or an orifice tube, is crucial for pressure and temperature reduction:

- Pressure Drop: This component drastically reduces the pressure of the liquid refrigerant coming from the receiver-drier. This pressure drop is essential because it causes a rapid temperature drop in the refrigerant.

- Refrigerant Control: Expansion valves are more sophisticated, automatically adjusting refrigerant flow based on cooling demand. Orifice tubes are simpler, fixed-size restrictions.

- State of Refrigerant: After passing through the metering device, the refrigerant remains a low-pressure, low-temperature liquid, ready for evaporation in the evaporator.

- Location: It is positioned on the high-pressure side, usually between the receiver-drier and the evaporator, often near the firewall of the vehicle.

Evaporator

The evaporator is where the magic of cooling happens inside your car. It’s the component that directly cools the cabin air:

- Heat Absorption: Low-pressure, low-temperature liquid refrigerant enters the evaporator. As warm air from the car’s cabin is blown across the evaporator coils by the blower fan, the refrigerant absorbs heat.

- Phase Change (Evaporation): The heat absorbed from the cabin air causes the liquid refrigerant to evaporate, turning back into a low-pressure gas. This evaporation process is what creates the cooling effect.

- Dehumidification: As the air cools rapidly while passing over the evaporator, moisture in the air condenses on the cold evaporator fins and is drained out of the vehicle. This dehumidification is why AC air is dry as well as cool.

- Location: The evaporator is the only AC component located inside the passenger compartment, typically behind the dashboard, within the HVAC (Heating, Ventilation, and Air Conditioning) unit.

The Refrigerant Cycle: A Step-by-Step Journey

To fully grasp how does the AC work in a car, tracing the refrigerant’s path is essential:

- Entry to Compressor (Low-Pressure Gas): The cycle begins with low-temperature, low-pressure refrigerant gas entering the compressor.

- Exit from Compressor (High-Pressure Gas): The compressor compresses the gas, increasing both its temperature and pressure. Hot, high-pressure gas exits the compressor.

- Condensation in Condenser (Gas to Liquid, Heat Release): The hot, high-pressure gas flows into the condenser. Here, it cools down and transitions into a high-pressure liquid, releasing heat to the outside air.

- Filtration and Drying (High-Pressure Liquid): The high-pressure liquid refrigerant then passes through the receiver-drier, where moisture and contaminants are removed.

- Pressure Reduction at Metering Device (High to Low Pressure Liquid): The refrigerant reaches the expansion valve or orifice tube, where its pressure is drastically reduced. It remains a liquid but is now at low pressure and low temperature.

- Evaporation in Evaporator (Liquid to Gas, Heat Absorption): The low-pressure, low-temperature liquid refrigerant enters the evaporator. As cabin air blows across the evaporator, the refrigerant absorbs heat and evaporates into a low-pressure gas, cooling the air in the process.

- Return to Compressor (Low-Pressure Gas): Finally, the low-pressure, low-temperature refrigerant gas returns to the compressor, restarting the cycle.

This continuous cycle of compression, condensation, expansion, and evaporation is what provides consistent cooling inside your car.

Common Car AC System Problems and Maintenance

Understanding how does the AC work in a car can also help you recognize potential issues. Because car AC systems are closed and pressurized, maintaining their integrity is vital.

-

Refrigerant Leaks: Leaks are a primary cause of AC failure. Refrigerant leaks can occur at any connection point, hose, or component seal. A leak reduces refrigerant charge, diminishing cooling performance and potentially damaging the compressor due to lack of lubrication. Simply recharging a leaking system is a temporary solution; the leak must be located and repaired.

-

Compressor Failure: Compressor failure can be caused by leaks (due to lack of lubrication), internal wear and tear, or electrical issues. Compressors are complex and expensive to replace.

-

Condenser Blockage: The condenser, positioned at the front, is susceptible to blockage from road debris, bugs, and dirt. Reduced airflow through the condenser hinders heat dissipation, reducing AC efficiency. Regular cleaning of the condenser fins can prevent this issue.

-

Electrical Problems: AC systems rely on electrical components – relays, switches, and sensors. Faulty electrical components can prevent the compressor from engaging or fans from operating.

-

Clogged Expansion Valve or Orifice Tube: Contaminants in the system can clog the metering device, restricting refrigerant flow and reducing cooling.

Basic Maintenance Tips:

- Regular AC Use: Even in winter, running your AC for a few minutes periodically can help circulate refrigerant and lubricant, keeping seals pliable and preventing compressor issues.

- Visual Inspection: Occasionally check the condenser for debris buildup and clean it if necessary.

- Professional Check-ups: Schedule periodic AC system checks with a qualified technician to identify and address minor issues before they become major problems.

Career Opportunities in Automotive AC Repair

With air conditioning now a standard feature in virtually every new car, the demand for skilled automotive AC technicians is consistent and strong. Technicians regularly diagnose and repair AC systems, addressing customer complaints ranging from warm air and unusual noises to water leaks inside the vehicle.

For those interested in a hands-on career in automotive technology, specializing in AC systems offers a valuable and marketable skill set. Programs like those offered at Universal Technical Institute (UTI) provide comprehensive training in all vehicle systems, including in-depth knowledge of AC diagnosis, repair, and maintenance.

FAQs About Car AC Systems

To further clarify how does the AC work in a car, let’s address some common questions:

Q: How does a car air conditioner cool the air?

A: A car AC cools air by using refrigerant to absorb heat and humidity from the air. The refrigerant evaporates in the evaporator, a process that requires heat, thus cooling the surrounding air. This cooled, dehumidified air is then blown into the car cabin.

Q: What are the main components of a car air conditioning system?

A: The primary components are the compressor, condenser, receiver-drier, metering device (expansion valve or orifice tube), and evaporator. Each plays a crucial role in the refrigerant cycle and the overall cooling process.

Q: How does refrigerant cool the air?

A: Refrigerant cools air through a phase change. As liquid refrigerant evaporates into a gas within the evaporator, it absorbs heat from the air passing over it. This heat absorption is what lowers the air temperature.

Start Your Automotive Technician Career Journey

If you’re fascinated by systems like car AC and are considering a career as an automotive technician, Universal Technical Institute (UTI) offers comprehensive training programs. In less than a year, you can gain the practical skills and knowledge needed for entry-level positions in the automotive industry. UTI’s programs cover all aspects of vehicle technology, ensuring graduates are well-prepared for the demands of modern automotive service.

Hands-on Training: Gain practical experience with industry-leading brands and equipment.

Flexible Start Dates: Classes begin every 3-6 weeks, allowing you to start your training sooner.

Explore Your Options: Get your questions answered and discover if a career as an automotive technician is the right path for you, with no obligation to enroll.

Related Articles

[

How Long Does It Take to Become an Automotive Mechanic?](/blog/education/automotive-technician-career)

Explore the path to becoming an auto mechanic and how UTI training can accelerate your career.

[

What Is an Automotive Service Writer and What Do They Do?](/blog/automotive/automotive-service-writer)

Learn about the role of an automotive service writer and career opportunities in this field.

[

The Automotive Technician Shortage: What Does This Mean for Your Career?](/blog/automotive/automotive-tech-shortage)

Understand the implications of the automotive technician shortage and the career advantages it presents.

Disclaimer: 1) UTI is an educational institution and cannot guarantee employment or salary. 2) For program outcome information and other disclosures, visit www.uti.edu/disclosures. 7) Some programs may require longer than one year to complete.

Universal Technical Institute of Illinois, Inc. is approved by the Division of Private Business and Vocational Schools of the Illinois Board of Higher Education.