The starter motor in your car is a small but incredibly powerful electric motor that plays a crucial role in getting your engine running. Without a functioning starter, your car simply won’t start. It’s the initial jolt of energy that turns the engine over, allowing the combustion process to begin and power all the other systems in your vehicle. Let’s delve into how this essential component works and what makes it so vital to your car’s operation.

The Role of the Starter Motor

The primary job of the starter motor is to crank your engine. Internal combustion engines require an external force to initiate the first few rotations, allowing the pistons to move, draw in air and fuel, and compress the mixture. This is where the starter motor comes in. It provides the necessary torque to overcome the engine’s inertia and start the combustion cycle. Think of it as the muscle that gets everything going under the hood.

Key Components and Working Principle

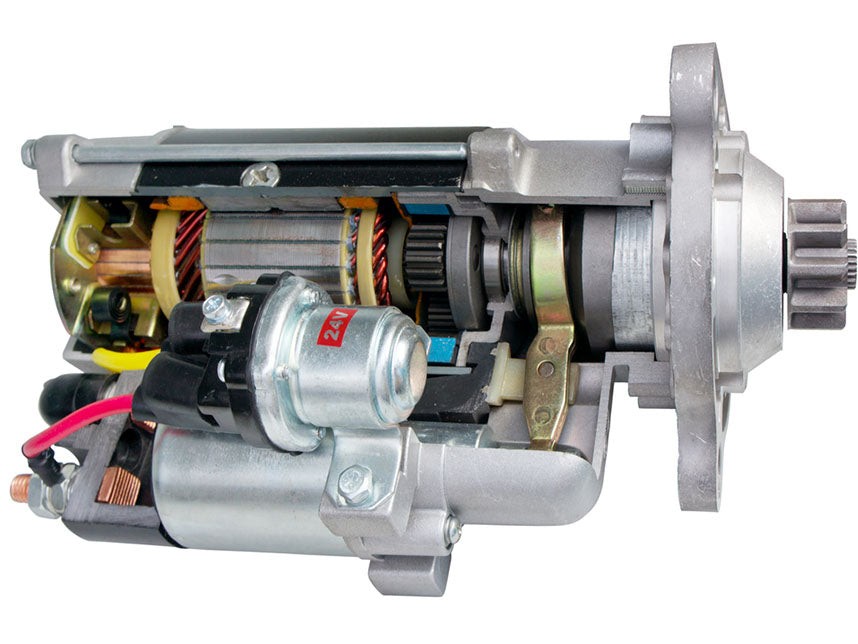

The magic behind the starter motor lies in a combination of electrical power and mechanical action. Here’s a breakdown of the key components and how they work together:

- Solenoid: This is essentially a heavy-duty electrical switch, often mounted directly on the starter motor. When you turn your ignition key, a small current is sent to the solenoid. This current energizes an electromagnet inside the solenoid.

- Plunger and Fork: The energized electromagnet in the solenoid pulls a plunger. This plunger serves two critical functions. First, it closes a set of heavy contacts, allowing a high-current flow from the battery directly to the starter motor itself. Second, it mechanically engages a fork.

- Pinion Gear: The fork, activated by the solenoid plunger, pushes a small gear called the pinion gear. This pinion gear is attached to the starter motor’s armature shaft. The fork action forces the pinion gear to mesh with the flywheel (or flexplate in automatic transmissions) of your engine. The flywheel is a large, toothed wheel that is connected to the engine’s crankshaft.

- Armature and Electric Motor: Once the solenoid has engaged the pinion gear and completed the high-current electrical circuit, the starter motor itself, a powerful DC electric motor, is energized. The armature inside the motor spins rapidly, turning the pinion gear which is now meshed with the flywheel. This rotation of the flywheel, driven by the starter motor, cranks the engine.

As soon as the engine starts and begins to run on its own power, you release the ignition key. This cuts power to the solenoid. A spring then retracts the plunger, disengaging the pinion gear from the flywheel. This disengagement is crucial to prevent the engine, now running much faster than the starter motor is designed for, from damaging the starter.

starter motor cutaway

starter motor cutaway

A Brief History: The Invention of the Electric Starter

Before electric starters, cars were cranked by hand, a laborious and sometimes dangerous process. The invention of the electric starter motor revolutionized the automotive world. Charles Kettering is credited with inventing the electric starter in 1911 for the 1912 Cadillac. His system integrated the starter, generator, and ignition, representing a major leap forward in automotive technology.

Vincent Bendix further refined the system by inventing the Bendix drive. This ingenious mechanism enabled the pinion gear to automatically engage and disengage with the flywheel, making the starting process both reliable and user-friendly. While early systems sometimes combined starter and generator functions, modern cars typically have separate, dedicated systems for each, although integrated starter-generators are making a comeback in hybrid vehicles.

Common Starter Motor Issues and Failures

Starter motors are robust, but they can fail over time. Here are some common issues:

- Battery Drain: The starter motor requires a massive surge of power from the battery. A weak or discharged battery is a frequent cause of starting problems. If you hear a rapid “click, click, click” when you turn the key, it’s often the solenoid attempting to engage but lacking sufficient power from the battery.

- Mechanical Wear: Like any mechanical component, starter motors experience wear and tear. Bearings can wear out, increasing friction and requiring more power to turn the motor. Eventually, this wear can prevent the starter from turning the engine fast enough to start.

- Electrical Problems: The solenoid itself can fail, or the internal windings of the starter motor can develop shorts or breaks in the insulation. Dirty or corroded connections within the solenoid or commutator can also impede electrical flow, leading to intermittent starting problems or complete failure. Sometimes heat buildup after driving can exacerbate these electrical issues, causing a starter to work when cold but fail when warm.

Troubleshooting Starter Problems

If your car is having trouble starting, it could be a starter issue, but it’s essential to rule out other possibilities first.

- Check the Battery: Ensure your battery is fully charged and in good condition. A battery test can confirm its health. Also, inspect battery cable connections for cleanliness and tightness. Loose or corroded connections can prevent sufficient power from reaching the starter.

- Listen for Clicks: A “click, click, click” sound usually points to a battery or solenoid issue. A single click might indicate a problem with the solenoid itself. No sound at all could be a more serious electrical problem or starter motor failure.

- Professional Testing: If you suspect the starter motor itself is faulty, most auto parts stores can test it for you once it’s removed from the vehicle. This can definitively confirm if the starter is the source of the problem.

Understanding how your car’s starter motor works can empower you to diagnose starting issues and appreciate the engineering that goes into even seemingly simple automotive systems. While starter motor replacement is a task often tackled by DIY mechanics, consulting a service manual like a Haynes Manual for your specific vehicle is always recommended for safe and effective repairs.