Crafting a mouse trap car involves ingenuity, engineering, and a bit of physics know-how. At CARS.EDU.VN, we understand the joy of hands-on projects. This guide provides a comprehensive walkthrough on creating your own high-performance mouse trap vehicle, with insights into design, materials, and troubleshooting, and explores related concepts like kinetic energy, potential energy, and friction reduction.

1. Understanding the Basics of a Mouse Trap Car

A mouse trap car is a small vehicle powered solely by the energy of a standard mouse trap. The beauty of this project lies in its simplicity and the challenge it presents in maximizing efficiency. To succeed, you need to understand the key principles at play. This project not only showcases fundamental physics concepts like Newton’s laws of motion and energy transfer but also fosters creativity and problem-solving skills.

1.1 The Core Components

- The Mouse Trap: This is your engine. The spring’s potential energy, when released, provides the force to propel the car. Understanding how to efficiently convert this energy into motion is key.

- The Lever Arm: A lever arm attached to the mouse trap’s snapper increases the distance over which the force is applied. The length of this lever arm is critical for controlling both the speed and the distance your car will travel.

- The Axle: The axle connects the lever arm to the wheels. The way you wind the string around the axle determines the number of rotations the wheels make for each snap of the trap.

- The Wheels: The size and material of the wheels affect the car’s speed and traction. Larger wheels cover more distance per rotation, while the wheel material influences friction and grip.

- The Chassis: The car’s body provides a stable platform for all other components. Its design affects the car’s weight distribution and aerodynamics.

1.2 Key Concepts

- Potential Energy: The energy stored in the mouse trap’s spring when it is set. Your goal is to convert as much of this potential energy as possible into kinetic energy.

- Kinetic Energy: The energy of motion. The car’s kinetic energy depends on its mass and velocity.

- Torque: A rotational force. The lever arm increases the torque applied to the axle, which in turn drives the wheels.

- Friction: A force that opposes motion. Reducing friction in the axles and between the wheels and the ground is crucial for maximizing distance.

2. Designing Your Mouse Trap Car

Before you start building, take the time to design your car. A well-thought-out design can make a huge difference in its performance.

2.1 Setting Performance Goals

What do you want your car to do? Are you aiming for maximum distance, maximum speed, or a balance of both? Defining your goals will guide your design choices. Consider the following:

- Distance: Prioritize a longer lever arm and larger wheels.

- Speed: Opt for smaller wheels and a shorter lever arm.

- Control: A stable chassis and a good steering mechanism will help your car travel in a straight line.

2.2 Choosing the Right Materials

The materials you use will impact the car’s weight, friction, and overall performance. Here’s a breakdown of common materials and their properties:

| Material | Properties | Advantages | Disadvantages |

|---|---|---|---|

| Balsa Wood | Lightweight, easy to cut, and shape | Very light, allows for easy customization | Can be fragile, may require reinforcement |

| Plywood | Stronger than balsa, still relatively lightweight | More durable than balsa, good for the chassis | Heavier than balsa, may require more effort to cut |

| PVC Pipe | Rigid, lightweight, and readily available | Excellent for axles and structural supports, reduces friction | Can be difficult to attach to other materials |

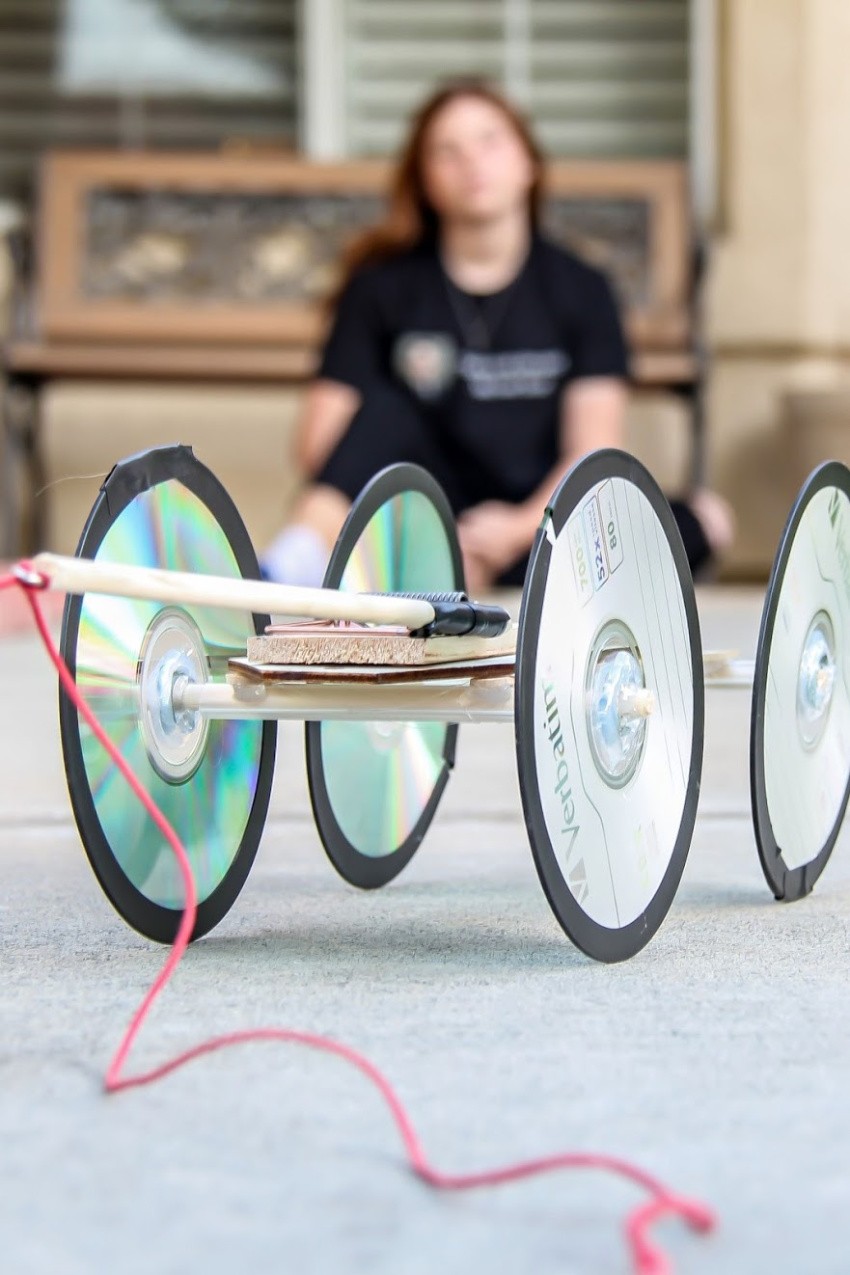

| CDs/DVDs | Circular, uniform, and lightweight | Ideal for wheels, provide a smooth rolling surface | Can be brittle, may crack under stress |

| Rubber Bands | Elastic, provide good traction | Can be used as tires for added grip | Can add weight, may increase friction if not properly fitted |

| Fishing Line | Strong, lightweight, and low friction | Excellent for connecting the lever arm to the axle | Can be difficult to handle, may require careful knotting |

| Metal Washers | Add weight and reduce friction | Can be used to balance the car and reduce friction on axles | Can add excessive weight if overused |

2.3 Creating a Detailed Sketch

Before you start cutting and gluing, create a detailed sketch of your car. Include dimensions, material specifications, and component placements. This will serve as your blueprint and help you stay organized.

3. Step-by-Step Guide to Building Your Mouse Trap Car

Here’s a detailed guide to assembling your mouse trap car.

3.1 Assembling the Chassis

- Cut the Base: Cut a piece of balsa wood or plywood to your desired dimensions. A longer chassis will provide more stability. Aim for a length of 12-18 inches and a width of 3-4 inches.

- Reinforce the Frame: If using balsa wood, reinforce the edges with popsicle sticks or additional strips of wood to prevent cracking.

- Attach Axle Supports: Glue small blocks of wood or PVC pipe sections to the chassis to support the axles. Ensure they are aligned properly to allow the wheels to rotate freely.

3.2 Installing the Axles and Wheels

- Prepare the Axles: Cut the wood dowel rods to the appropriate length for the front and rear axles. The length will depend on the width of your chassis and wheels.

- Attach the Wheels: Secure the wheels to the axles using hot glue. Ensure they are centered and aligned to prevent wobbling. If using CDs/DVDs, consider reinforcing them with cardboard or plastic discs to prevent cracking.

- Reduce Friction: Apply a small amount of lubricant (such as graphite powder or silicone spray) to the axles where they contact the supports. This will significantly reduce friction.

3.3 Mounting the Mouse Trap

- Position the Mouse Trap: Place the mouse trap on the chassis, towards the rear. Experiment with different positions to find the optimal balance.

- Secure the Mouse Trap: Use hot glue or screws to securely attach the mouse trap to the chassis. Ensure it is firmly in place and won’t shift during operation.

- Attach the Lever Arm: Cut a length of wood or metal to serve as the lever arm. Attach one end to the mouse trap’s snapper using glue or screws. The length of the lever arm will determine the car’s torque and speed.

3.4 Connecting the Lever Arm to the Axle

- Install the Eye Screw: Screw an eye screw into the end of the lever arm. This will serve as the attachment point for the string.

- Attach the String: Tie one end of the fishing line or cord to the eye screw. Wrap the other end around the rear axle. The number of wraps will determine the distance the car travels per snap of the trap.

- Adjust the String Length: Experiment with different string lengths to find the optimal balance between speed and distance.

3.5 Fine-Tuning and Adjustments

- Test Run: Wind the string around the axle, set the mouse trap, and release the car. Observe its performance and make adjustments as needed.

- Adjust Wheel Alignment: If the car veers to one side, adjust the alignment of the wheels by slightly bending the axles or adding shims.

- Adjust Lever Arm Length: Experiment with different lever arm lengths to optimize speed and distance.

- Add Weight: Add small weights (such as metal washers) to the chassis to improve traction and stability.

- Lubricate Axles: Reapply lubricant to the axles as needed to minimize friction.

4. Optimizing Performance

Once you have a basic working model, you can start optimizing its performance.

4.1 Maximizing Distance

- Longer Lever Arm: Increases the torque applied to the axle, allowing the car to travel further per snap of the trap.

- Larger Wheels: Cover more distance per rotation.

- Low-Friction Axles: Minimize energy loss due to friction.

- Lightweight Chassis: Reduces the amount of energy required to move the car.

4.2 Increasing Speed

- Shorter Lever Arm: Decreases the torque, resulting in faster wheel rotation.

- Smaller Wheels: Require less torque to accelerate quickly.

- High-Traction Tires: Provide better grip for faster acceleration.

- Aerodynamic Design: Reduces air resistance.

4.3 Reducing Friction

- Lubrication: Use graphite powder or silicone spray on axles and other moving parts.

- Precision Bearings: Replace simple axle supports with ball bearings or bushings for smoother rotation.

- Wheel Alignment: Ensure wheels are perfectly aligned to minimize rolling resistance.

- Lightweight Materials: Reduce the overall weight of the car to minimize friction.

5. Troubleshooting Common Problems

Even with careful planning, you may encounter problems during the building process. Here are some common issues and their solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Car doesn’t move | Mouse trap not properly set, string not properly attached | Ensure mouse trap is fully set, check string attachment |

| Car moves in circles | Misaligned wheels, uneven weight distribution | Adjust wheel alignment, redistribute weight |

| Car stops after a short distance | Excessive friction, insufficient torque | Lubricate axles, increase lever arm length |

| Wheels slip | Insufficient traction, excessive torque | Add rubber bands to wheels, shorten lever arm |

| Chassis is unstable | Weak frame, uneven weight distribution | Reinforce frame, redistribute weight |

| String slips on the axle | Smooth axle surface, insufficient tension | Roughen axle surface with sandpaper, increase string tension |

| Lever arm breaks | Weak material, excessive force | Use stronger material for lever arm, reduce string tension |

6. Advanced Techniques

Once you’ve mastered the basics, you can explore more advanced techniques to further improve your car’s performance.

6.1 Variable Gearing

Implement a system that changes the gear ratio as the mouse trap unwinds. This can optimize torque and speed throughout the car’s run.

6.2 Energy Storage

Use a flywheel or other energy storage device to capture and release energy more efficiently.

6.3 Aerodynamic Design

Streamline the car’s body to reduce air resistance and increase speed.

6.4 Suspension System

Incorporate a suspension system to absorb bumps and maintain traction on uneven surfaces.

7. Safety Precautions

Working with tools and mechanical devices can be dangerous. Always follow these safety precautions:

- Wear safety glasses to protect your eyes.

- Use caution when working with sharp tools.

- Supervise children closely during the building process.

- Never point the mouse trap at yourself or others when setting it.

- Dispose of broken or damaged parts properly.

8. Examples of Successful Mouse Trap Cars

To inspire your own design, here are some examples of successful mouse trap cars:

- The “Distance King”: Features a long lever arm, large wheels, and ultra-low-friction axles for maximum distance.

- The “Speed Demon”: Utilizes a short lever arm, small wheels, and high-traction tires for blistering speed.

- The “Hybrid”: Combines elements of both distance and speed designs for a balanced performance.

- The “Engineering Marvel”: A more complex design that uses advanced techniques like variable gearing or energy storage.

9. The Science Behind Mouse Trap Cars

Building a mouse trap car is not just a fun project; it’s also a great way to learn about physics and engineering principles.

9.1 Newton’s Laws of Motion

- First Law (Inertia): A body at rest stays at rest, and a body in motion stays in motion with the same speed and in the same direction unless acted upon by a force.

- Second Law (F=ma): The force acting on an object is equal to the mass of that object times its acceleration.

- Third Law (Action-Reaction): For every action, there is an equal and opposite reaction.

9.2 Energy Conservation

The total energy of an isolated system remains constant. In a mouse trap car, potential energy is converted into kinetic energy, with some energy lost due to friction.

9.3 Mechanical Advantage

The lever arm provides mechanical advantage by increasing the torque applied to the axle.

10. Why This Project Matters

Building a mouse trap car is more than just a fun science project; it’s an exercise in creativity, problem-solving, and engineering. It teaches valuable skills that can be applied to many areas of life.

10.1 Educational Benefits

- Reinforces physics and engineering concepts.

- Develops problem-solving and critical thinking skills.

- Encourages creativity and innovation.

- Promotes teamwork and collaboration.

- Provides hands-on learning experience.

10.2 Real-World Applications

The principles learned from building a mouse trap car can be applied to real-world engineering problems, such as designing efficient vehicles, developing renewable energy sources, and creating innovative mechanical devices.

11. Engaging with the Community

Share your mouse trap car projects, tips, and tricks with the online community. Collaborate with others, learn from their experiences, and inspire them with your own creations.

11.1 Online Forums

Participate in online forums and discussion groups dedicated to mouse trap cars.

11.2 Social Media

Share your projects on social media platforms using relevant hashtags.

11.3 Competitions

Enter mouse trap car competitions and test your skills against other builders.

12. Staying Up-to-Date

The world of mouse trap cars is constantly evolving, with new materials, techniques, and designs emerging all the time. Stay up-to-date with the latest trends and innovations by following online forums, reading scientific articles, and attending workshops and competitions.

12.1 Online Resources

Explore online resources such as websites, blogs, and videos dedicated to mouse trap cars.

12.2 Scientific Journals

Read scientific articles on related topics such as mechanics, energy conservation, and friction reduction.

12.3 Workshops and Competitions

Attend workshops and competitions to learn from experts and see the latest designs in action.

13. Innovations in Mouse Trap Car Design

The basic concept of a mouse trap car has been around for years, but that doesn’t mean there isn’t room for innovation. Here are some of the latest trends in mouse trap car design:

13.1 Use of 3D-Printed Parts

3D printing allows for the creation of complex and customized parts, such as gears, wheels, and chassis components.

13.2 Incorporation of Sensors and Microcontrollers

Sensors and microcontrollers can be used to monitor and control various aspects of the car’s performance, such as speed, distance, and acceleration.

13.3 Development of Novel Energy Storage Devices

Researchers are exploring new ways to store and release energy, such as using supercapacitors or advanced spring mechanisms.

14. Maintenance and Longevity

To ensure your mouse trap car performs well for a long time, proper maintenance is essential.

14.1 Regular Inspection

Inspect your car regularly for signs of wear and tear, such as loose screws, cracked wheels, or frayed strings.

14.2 Cleaning and Lubrication

Keep your car clean and lubricated to minimize friction and prevent corrosion.

14.3 Part Replacement

Replace worn or damaged parts as needed to maintain optimal performance.

15. The Role of Mouse Trap Cars in Education

Mouse trap cars are valuable tools for educators looking to engage students in science, technology, engineering, and mathematics (STEM) learning.

15.1 Curriculum Integration

Mouse trap cars can be integrated into various STEM curricula, such as physics, engineering, and technology.

15.2 Hands-On Learning

Building a mouse trap car provides students with a hands-on learning experience that reinforces theoretical concepts.

15.3 Skill Development

Working on a mouse trap car project helps students develop critical thinking, problem-solving, and teamwork skills.

16. Future Trends in Mouse Trap Car Technology

As technology continues to advance, the future of mouse trap cars is likely to be shaped by new materials, designs, and control systems.

16.1 Use of Smart Materials

Smart materials that can change their properties in response to external stimuli could be used to optimize the car’s performance.

16.2 Integration of Artificial Intelligence

AI algorithms could be used to control the car’s movements and optimize its performance in real-time.

16.3 Development of Wireless Control Systems

Wireless control systems could allow users to remotely control and monitor the car’s performance.

17. Ethical Considerations

When building and competing with mouse trap cars, it’s important to consider ethical issues such as fair play, safety, and environmental responsibility.

17.1 Fair Play

Follow the rules of the competition and avoid using unfair or unethical tactics.

17.2 Safety

Prioritize safety during the building and testing process.

17.3 Environmental Responsibility

Use environmentally friendly materials and dispose of waste properly.

18. Resources for Further Learning

To deepen your knowledge of mouse trap cars and related topics, here are some resources for further learning:

18.1 Books

Read books on mechanics, energy conservation, and engineering design.

18.2 Online Courses

Take online courses on physics, engineering, and STEM education.

18.3 Educational Websites

Explore educational websites and online resources dedicated to mouse trap cars.

19. Legal Aspects

When building and competing with mouse trap cars, be aware of any legal restrictions or regulations that may apply.

19.1 Competition Rules

Familiarize yourself with the rules of the competition and ensure your car complies with all requirements.

19.2 Safety Regulations

Follow all applicable safety regulations and guidelines.

19.3 Intellectual Property

Respect the intellectual property rights of others and avoid copying or infringing on patented designs.

20. Case Studies of Successful Designs

To provide inspiration and guidance, here are several detailed case studies of successful mouse trap car designs, analyzing their strengths, weaknesses, and unique features.

20.1 The “Lightweight Champion”

This design focuses on minimizing weight through the use of balsa wood and lightweight wheels, maximizing efficiency and distance.

20.2 The “Torque Master”

Emphasizing torque over speed, this car utilizes a longer lever arm and a carefully chosen gear ratio to conquer challenging terrains.

20.3 The “Aerodynamic Ace”

With a streamlined chassis and strategically placed wings, this design minimizes air resistance, resulting in impressive speed and agility.

20.4 The “All-Terrain Vehicle”

Engineered to handle various surfaces, this car features a robust suspension system and high-traction tires, ensuring consistent performance in any environment.

21. The Psychology of Problem-Solving

Building a mouse trap car is a challenging task that requires creative problem-solving skills.

21.1 Identifying the Problem

Clearly define the problem you are trying to solve.

21.2 Brainstorming Solutions

Generate a list of possible solutions.

21.3 Evaluating Options

Evaluate the pros and cons of each solution.

21.4 Implementing the Solution

Put your chosen solution into action.

21.5 Testing and Refining

Test your solution and make adjustments as needed.

22. Building Your Own Mouse Trap Car Community

Creating a local community around mouse trap car enthusiasts can enhance the building experience and foster collaboration.

22.1 Starting a Club

Organize a local mouse trap car club and host regular meetings and workshops.

22.2 Organizing Competitions

Host local mouse trap car competitions and invite builders from other communities to participate.

22.3 Mentoring New Builders

Provide guidance and support to new builders and help them develop their skills.

23. The Impact of Mouse Trap Cars on Popular Culture

Mouse trap cars have captured the imagination of people around the world and have been featured in movies, TV shows, and books.

23.1 Movie Appearances

Mouse trap cars have made appearances in movies such as “The Great Mouse Detective” and “Honey, I Shrunk the Kids”.

23.2 TV Show Mentions

Mouse trap cars have been mentioned on TV shows such as “The Big Bang Theory” and “MythBusters”.

23.3 Book References

Mouse trap cars have been referenced in books such as “The Art of Problem Solving” and “Engineering for Dummies”.

24. Global Variations

Mouse trap car designs vary around the world, reflecting local materials, cultural influences, and competition rules.

24.1 European Designs

European designs often emphasize precision engineering and the use of high-quality materials.

24.2 Asian Designs

Asian designs often incorporate traditional craftsmanship and innovative energy storage systems.

24.3 American Designs

American designs often focus on speed and performance, with an emphasis on aerodynamics and lightweight materials.

25. The Future of STEM Education

Mouse trap cars are a valuable tool for promoting STEM education and preparing students for the challenges of the 21st century.

25.1 Hands-On Learning

Mouse trap cars provide students with a hands-on learning experience that reinforces theoretical concepts.

25.2 Skill Development

Working on a mouse trap car project helps students develop critical thinking, problem-solving, and teamwork skills.

25.3 Career Preparation

Mouse trap car projects can inspire students to pursue careers in STEM fields such as engineering, physics, and computer science.

26. The Importance of Iteration

The key to building a successful mouse trap car is iteration, the process of repeatedly testing, analyzing, and refining your design.

26.1 Testing and Analysis

Thoroughly test your car and analyze its performance.

26.2 Identifying Weaknesses

Identify any weaknesses in your design.

26.3 Implementing Improvements

Implement improvements to address the weaknesses.

26.4 Retesting

Retest the car to ensure the improvements have had the desired effect.

26.5 Repeating the Process

Repeat the process of testing, analyzing, and refining until you have achieved your desired performance.

27. Inspiring Stories of Innovation

Throughout history, many individuals and teams have achieved remarkable feats of innovation with mouse trap cars.

27.1 Record-Breaking Distances

Some builders have achieved record-breaking distances with their mouse trap cars, surpassing hundreds of feet.

27.2 Unconventional Materials

Some builders have used unconventional materials such as carbon fiber and exotic woods to achieve exceptional performance.

27.3 Advanced Designs

Some builders have created advanced designs with features such as variable gearing, energy storage, and AI control.

28. Alternative Power Sources

While mouse traps are the most common power source for these cars, exploring alternative methods can lead to unique challenges and learning opportunities.

28.1 Rubber Band Power

Utilizing the elastic potential energy of a rubber band can offer a different approach to propulsion.

28.2 Spring Mechanisms

Experimenting with different spring mechanisms can provide valuable insights into energy storage and release.

28.3 Solar Power

Integrating a small solar panel and motor can introduce concepts of renewable energy.

29. Maximizing Audience Engagement

Creating content about mouse trap cars that is both informative and engaging is essential for reaching a wider audience.

29.1 Visual Aids

Use high-quality images and videos to illustrate the building process and showcase successful designs.

29.2 Interactive Elements

Incorporate interactive elements such as quizzes, polls, and simulations to engage the audience.

29.3 Storytelling

Share inspiring stories of innovation and success to capture the imagination of the audience.

30. Connecting Theory to Practice

Bridge the gap between theoretical concepts and practical applications through hands-on learning experiences.

30.1 Demonstrations

Conduct live demonstrations to illustrate the principles of physics and engineering.

30.2 Experiments

Design experiments to test different designs and materials.

30.3 Real-World Examples

Relate the concepts learned to real-world examples of engineering and technology.

Building a mouse trap car is an exciting and rewarding project that combines creativity, problem-solving, and engineering skills. By following the steps outlined in this guide, you can build your own high-performance mouse trap car and learn valuable lessons about physics, engineering, and teamwork.

Ready to dive deeper into the world of automotive engineering and find expert service and repair solutions? Visit CARS.EDU.VN today. Whether you’re seeking detailed maintenance guides, troubleshooting tips, or trusted service providers, we’re here to help. Contact us at 456 Auto Drive, Anytown, CA 90210, United States, or reach out via Whatsapp at +1 555-123-4567. Let CARS.EDU.VN be your go-to resource for all things automotive.

Instructions for building a mousetrap vehicle for a successful science project.

Instructions for building a mousetrap vehicle for a successful science project.

FAQ About Mouse Trap Cars

Q1: What is the basic principle behind a mouse trap car?

A mouse trap car is powered by the energy stored in the spring of a mouse trap. When the trap is released, this energy is converted into kinetic energy, which propels the car forward.

Q2: What materials are best for building a mouse trap car?

Common materials include balsa wood, plywood, CDs/DVDs, rubber bands, fishing line, and metal washers. The choice of materials depends on your design goals and budget.

Q3: How can I maximize the distance my mouse trap car travels?

To maximize distance, use a longer lever arm, larger wheels, low-friction axles, and a lightweight chassis.

Q4: How can I increase the speed of my mouse trap car?

To increase speed, use a shorter lever arm, smaller wheels, high-traction tires, and an aerodynamic design.

Q5: What are some common problems with mouse trap cars and how can I fix them?

Common problems include the car not moving, moving in circles, or stopping after a short distance. These can be fixed by adjusting wheel alignment, lubricating axles, and redistributing weight.

Q6: What is the role of the lever arm in a mouse trap car?

The lever arm increases the torque applied to the axle, which in turn drives the wheels. The length of the lever arm affects the car’s speed and distance.

Q7: How does friction affect the performance of a mouse trap car?

Friction opposes motion and reduces the efficiency of the car. Minimizing friction in the axles and between the wheels and the ground is crucial for maximizing distance.

Q8: What safety precautions should I take when building a mouse trap car?

Wear safety glasses, use caution when working with sharp tools, supervise children closely, and never point the mouse trap at yourself or others when setting it.

Q9: Can I use alternative power sources for a mouse trap car?

Yes, alternative power sources include rubber bands, spring mechanisms, and solar power.

Q10: Where can I find more resources for learning about mouse trap cars?

You can find more resources online, in books, and at workshops and competitions. cars.edu.vn also offers detailed guides and information on automotive engineering and mechanics.