Building a Pinewood Derby car is a fantastic project, and CARS.EDU.VN is here to guide you through every step. Discover How To Build A Pinewood Derby Car that’s both fast and visually appealing, focusing on design, lubrication, and weight distribution. Ready to elevate your car building skills and explore expert insights into automotive craftsmanship? Let’s dive into aerodynamics, axle polishing, and performance enhancement.

1. Understanding the Pinewood Derby: More Than Just a Race

The Pinewood Derby is a beloved tradition that combines craftsmanship, competition, and camaraderie. It’s an opportunity for Scouts and their families to work together, learn about physics and engineering, and create lasting memories. More than just a race, it’s a project that encourages creativity, problem-solving, and good sportsmanship. This is an event where CARS.EDU.VN encourages innovation and skillful building in a fun, competitive way.

1.1. The History and Significance of the Pinewood Derby

The Pinewood Derby was created in 1953 by Cub Scout leader Don Murphy as a constructive alternative to the usual activities. Since then, it has become a staple of Cub Scouting, teaching children about physics, design, and the satisfaction of building something with their own hands. Its significance lies in its ability to foster creativity, problem-solving skills, and family bonding.

According to the Boy Scouts of America, the Pinewood Derby is “one of the most popular and successful events in Cub Scouting.” (Source: scouting.org)

1.2. Key Rules and Regulations for Pinewood Derby Cars

Before you start building, it’s essential to know the rules. These can vary slightly by pack, but generally include limitations on weight, dimensions, and the use of certain materials. Common regulations include:

- Weight Limit: Typically 5 ounces (141.75 grams)

- Dimensions: Maximum length, width, and height

- Wheels and Axles: Must use official kit components, with restrictions on modifications

- Lubrication: Usually limited to graphite or dry lubricants

It’s important to consult your local pack’s rules to ensure your car complies with all regulations, ensuring a fair and fun competition. Ignoring the rules can lead to disqualification, so always double-check!

1.3. The Science Behind Speed: Physics for Pinewood Derby Cars

Several physics principles come into play when building a fast Pinewood Derby car. These include:

- Gravity: The driving force behind the car’s acceleration

- Friction: A force that opposes motion, which you want to minimize

- Aerodynamics: The shape of the car affects how it moves through the air

- Inertia: The tendency of an object to resist changes in its motion

- Potential and Kinetic Energy: Converting potential energy at the top of the track into kinetic energy as the car moves

Understanding these principles can help you make informed decisions about your car’s design and construction. CARS.EDU.VN recommends exploring these concepts to maximize your car’s performance.

2. Essential Tools and Materials for Building Your Derby Car

Before starting your build, gather all the necessary tools and materials to ensure a smooth and efficient process. Here’s a comprehensive list to help you get started:

2.1. Basic Hand Tools: What You’ll Need to Get Started

- Wood Saw: For cutting the basic shape of your car

- Hand Drill or Drill Press: For drilling axle holes

- Sandpaper (Various Grits): For smoothing the car body and axles

- Wood File or Rasp: For shaping and refining the car’s design

- Screwdrivers: For attaching weights and accessories

- Pencil and Ruler: For marking and measuring dimensions

These basic tools will form the foundation of your Pinewood Derby toolkit. Ensure they are in good condition and properly maintained for optimal performance.

2.2. Power Tools for Precision: Taking Your Car to the Next Level

- Belt Sander: For rapid material removal and shaping

- Disc Sander: For creating smooth, flat surfaces

- Drill Press: For precise and consistent axle hole drilling

- Dremel Tool: For detailed carving, sanding, and polishing

Power tools can significantly enhance the precision and efficiency of your build, but always use them with caution and proper safety equipment. CARS.EDU.VN stresses the importance of safety when using power tools.

2.3. Lubricants and Polishing Compounds: Reducing Friction for Speed

- Graphite Powder: The primary lubricant for axles

- Polishing Compound: For smoothing and polishing axles

- Metal Polish: For enhancing the smoothness of metal surfaces

High-quality lubricants and polishing compounds are essential for minimizing friction and maximizing your car’s speed. Choose products specifically designed for Pinewood Derby cars for the best results.

2.4. Safety Gear: Protecting Yourself During the Building Process

- Safety Goggles: To protect your eyes from flying debris

- Dust Mask: To prevent inhalation of sawdust and particles

- Gloves: To protect your hands from cuts and abrasions

Safety should always be your top priority when working with tools and materials. Wear appropriate safety gear at all times to prevent injuries and ensure a safe building experience.

3. Designing Your Pinewood Derby Car: From Concept to Reality

The design phase is where your creativity comes to life. Here’s how to develop a winning design for your Pinewood Derby car:

3.1. Brainstorming Design Ideas: Unleashing Your Creativity

Start by sketching out different design ideas on paper. Consider factors such as:

- Aerodynamics: Streamlined shapes reduce air resistance.

- Weight Distribution: Concentrating weight towards the rear can improve speed.

- Aesthetics: Choose a design that is visually appealing and reflects your personality.

- Simplicity: A simple, well-executed design can often outperform a complex one.

Don’t be afraid to experiment with different shapes and concepts. The more ideas you generate, the better your chances of finding a winning design. CARS.EDU.VN encourages you to explore unconventional designs.

3.2. Selecting the Right Car Shape: Aerodynamics and Stability

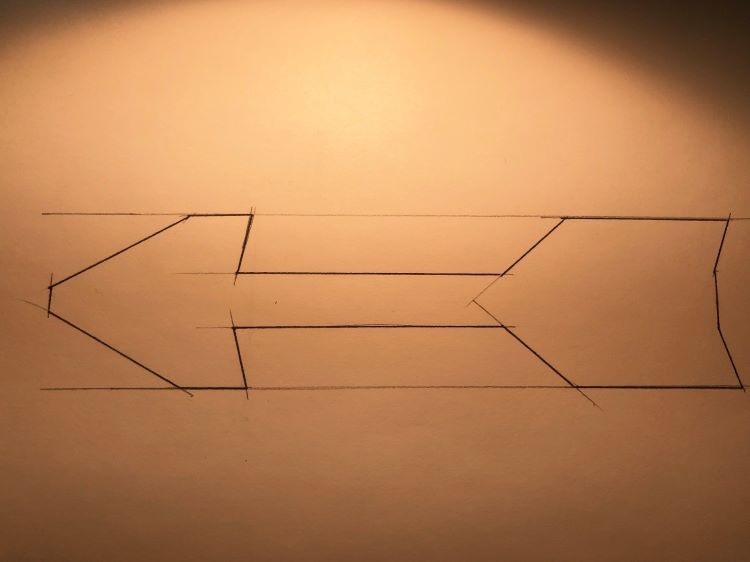

Some popular and effective car shapes include:

- Wedge: A classic, aerodynamic shape that reduces air resistance

- Arrow: Similar to the wedge, but with a more pointed front

- Rail: A slim, lightweight design that minimizes friction

- Bullet: A rounded shape that offers good aerodynamics

Consider the pros and cons of each shape and choose one that best suits your goals and resources. Aerodynamic efficiency and stability are key to maximizing speed.

3.3. Weight Placement Strategies: Optimizing for Speed and Performance

Proper weight placement is crucial for achieving optimal speed. Here are some strategies to consider:

- Rear Weight Bias: Concentrating weight towards the rear of the car increases its potential energy and improves acceleration.

- Low Center of Gravity: Keeping the weight low to the ground enhances stability and reduces the risk of wobbling.

- Adjustable Weight: Using removable weights allows you to fine-tune the car’s performance.

Experiment with different weight configurations to find the optimal balance for your car. Precision and attention to detail are essential for success.

3.4. Creating a Detailed Blueprint: Accuracy and Precision

Once you’ve finalized your design, create a detailed blueprint with precise measurements and dimensions. This blueprint will serve as your guide during the construction process, ensuring accuracy and consistency.

Include the following details in your blueprint:

- Overall length, width, and height

- Placement of axle holes

- Weight distribution

- Aerodynamic features

A well-executed blueprint is essential for translating your design ideas into a tangible, high-performance Pinewood Derby car. CARS.EDU.VN recommends using CAD software for precise blueprints.

Pinewood Derby car blueprint sketch with dimensions

Pinewood Derby car blueprint sketch with dimensions

4. Constructing Your Pinewood Derby Car: Step-by-Step Guide

With your design in place, it’s time to start building. Follow these step-by-step instructions to construct your Pinewood Derby car:

4.1. Cutting and Shaping the Car Body: Precision and Accuracy

- Transfer Your Design: Use your blueprint to transfer the car’s shape onto the wood block.

- Rough Cut: Use a saw to cut out the basic shape of the car. Leave some extra material for shaping and sanding.

- Shaping: Use a wood file, rasp, or belt sander to refine the car’s shape and contours.

- Sanding: Use progressively finer grits of sandpaper to smooth the car’s surface.

Take your time and pay attention to detail to ensure a smooth, accurate finish. Precision and accuracy are key to achieving optimal performance.

4.2. Preparing the Axle Holes: Ensuring Proper Alignment

- Mark the Axle Hole Locations: Use your blueprint to mark the precise locations of the axle holes.

- Drill Pilot Holes: Use a small drill bit to create pilot holes for the axles.

- Enlarge the Holes: Use a larger drill bit to enlarge the axle holes to the appropriate diameter.

- Check Alignment: Use an axle alignment tool to ensure the axle holes are perfectly aligned.

Proper axle alignment is crucial for minimizing friction and maximizing speed. Take your time and use precision tools to ensure accurate results. CARS.EDU.VN notes that misaligned axles are a common cause of slow cars.

4.3. Preparing the Wheels and Axles: Minimizing Friction for Speed

- Remove Imperfections: Use sandpaper or a polishing compound to remove any imperfections from the wheels and axles.

- Polish the Axles: Use a polishing wheel or Dremel tool to polish the axles to a smooth, mirror-like finish.

- Lubricate the Axles: Apply a small amount of graphite powder to the axles.

- Test the Wheels: Spin the wheels to ensure they rotate freely and smoothly.

Smooth, polished, and lubricated wheels and axles are essential for minimizing friction and maximizing speed. Pay attention to detail and use high-quality lubricants for best results.

4.4. Adding Weight to the Car: Achieving Optimal Weight Distribution

- Determine Weight Placement: Based on your design, determine the optimal location for adding weight to the car.

- Attach Weights: Use glue, screws, or epoxy to attach weights to the car.

- Secure Weights: Ensure the weights are securely attached and won’t come loose during the race.

- Check Weight: Use a Pinewood Derby scale to ensure the car meets the weight limit.

Proper weight placement is crucial for achieving optimal speed and stability. Experiment with different weight configurations to find the best balance for your car. CARS.EDU.VN suggests using tungsten weights for maximum density.

5. Fine-Tuning Your Pinewood Derby Car: Optimizing for Performance

Once your car is assembled, it’s time to fine-tune its performance. Here’s how to optimize your Pinewood Derby car for speed and consistency:

5.1. Axle Alignment Adjustments: Ensuring Straight and True Tracking

- Test Track: Use a test track to evaluate the car’s performance.

- Observe Tracking: Watch how the car tracks down the track. Does it veer to one side or wobble?

- Adjust Axles: Use pliers or an axle bending tool to make slight adjustments to the axle alignment.

- Re-Test: Re-test the car after each adjustment to evaluate the results.

Precise axle alignment is essential for ensuring straight and true tracking. Take your time and make small adjustments until the car performs optimally.

5.2. Wheel Polishing and Lubrication: Reducing Friction to a Minimum

- Re-Polish Wheels: Use a polishing compound to re-polish the wheels to a smooth finish.

- Re-Lubricate Axles: Apply a fresh coat of graphite powder to the axles.

- Burnish the Graphite: Spin the wheels to burnish the graphite into the axle surfaces.

- Test Spin: Test spin the wheels to ensure they rotate freely and smoothly.

Wheel polishing and lubrication are ongoing processes that should be performed regularly to maintain optimal performance. CARS.EDU.VN recommends using a high-quality graphite lubricant for best results.

5.3. Weight Distribution Refinement: Finding the Perfect Balance

- Evaluate Performance: Observe how the car performs on the test track. Does it accelerate quickly? Does it maintain its speed throughout the race?

- Adjust Weight: Add or remove small amounts of weight to fine-tune the car’s balance.

- Re-Test: Re-test the car after each adjustment to evaluate the results.

- Optimize: Continue making adjustments until you find the perfect weight distribution for optimal performance.

Weight distribution refinement is an iterative process that requires patience and attention to detail. Experiment with different weight configurations to find the best balance for your car.

5.4. Testing and Practice Runs: Evaluating Performance and Consistency

- Set Up Test Track: Set up a test track that is similar to the official race track.

- Perform Multiple Runs: Perform multiple test runs to evaluate the car’s performance and consistency.

- Record Results: Record the results of each run, including times and observations.

- Analyze Data: Analyze the data to identify any areas for improvement.

Testing and practice runs are essential for identifying and addressing any remaining issues with your car. Use the data you collect to make informed decisions about further adjustments.

6. Advanced Techniques for Pinewood Derby Cars: Taking It to the Next Level

For those looking to gain a competitive edge, here are some advanced techniques to consider:

6.1. Bent Axles: Achieving a “Rail Rider” Effect

- Bend Axles: Use an axle bending tool to bend one or more axles slightly.

- Create Rail Rider Effect: The bent axle will cause the car to “rail ride” along one edge of the track, reducing friction and improving speed.

- Fine-Tune: Fine-tune the axle bend to achieve optimal performance.

Bent axles can be a highly effective technique for improving speed, but they require precision and expertise. Use caution and consult with experienced builders before attempting this technique.

6.2. Polishing Wheels to a Mirror Finish: Reducing Surface Friction

- Use Fine-Grit Abrasives: Use progressively finer grits of sandpaper and polishing compounds to polish the wheels to a mirror finish.

- Remove Imperfections: Ensure all imperfections and scratches are removed from the wheel surfaces.

- Achieve Mirror Finish: The goal is to achieve a smooth, reflective surface that minimizes friction.

Polishing wheels to a mirror finish can significantly reduce surface friction and improve speed. This technique requires patience and attention to detail. CARS.EDU.VN recommends using a specialized wheel polishing kit.

6.3. Using Tungsten Weights: Maximizing Weight in a Small Space

- Dense Material: Tungsten is a very dense material, allowing you to add more weight in a smaller space.

- Optimize Weight Distribution: This can be particularly useful for optimizing weight distribution in tight spaces.

- Secure Weights: Use epoxy or other strong adhesive to securely attach the tungsten weights to the car.

Tungsten weights are an excellent choice for maximizing weight in a small space. They can be particularly useful for achieving a rear weight bias.

6.4. Aerodynamic Modifications: Minimizing Air Resistance

- Streamline Shape: Streamline the car’s shape to reduce air resistance.

- Add Fairings: Consider adding fairings or other aerodynamic features to further reduce drag.

- Test in Wind Tunnel: If possible, test the car in a wind tunnel to evaluate the effectiveness of your aerodynamic modifications.

Aerodynamic modifications can have a significant impact on speed, particularly at higher velocities. Experiment with different shapes and features to find the optimal aerodynamic configuration.

7. Safety First: Essential Precautions for Building Your Derby Car

Safety should always be your top priority when building your Pinewood Derby car. Here are some essential precautions to keep in mind:

7.1. Wearing Safety Goggles and a Dust Mask: Protecting Your Eyes and Lungs

- Safety Goggles: Always wear safety goggles to protect your eyes from flying debris and particles.

- Dust Mask: Wear a dust mask to prevent inhalation of sawdust and other harmful particles.

Protecting your eyes and lungs is essential for preventing injuries and maintaining good health.

7.2. Supervising Children When Using Tools: Ensuring a Safe Building Environment

- Close Supervision: Always supervise children closely when they are using tools.

- Teach Proper Use: Teach children how to use tools safely and properly.

- Enforce Rules: Enforce safety rules and guidelines at all times.

Supervising children is crucial for ensuring a safe and productive building environment.

7.3. Working in a Well-Ventilated Area: Preventing Exposure to Harmful Fumes

- Adequate Ventilation: Work in a well-ventilated area to prevent exposure to harmful fumes and particles.

- Open Windows: Open windows and doors to allow fresh air to circulate.

- Use a Fan: Use a fan to help ventilate the area.

Proper ventilation is essential for preventing exposure to harmful fumes and maintaining good health.

7.4. Proper Storage of Tools and Materials: Keeping Your Workspace Organized and Safe

- Designated Storage Areas: Designate specific storage areas for tools and materials.

- Keep Tools Sharp: Keep tools sharp and well-maintained.

- Store Materials Properly: Store materials properly to prevent accidents and injuries.

Proper storage of tools and materials is essential for maintaining a safe, organized, and efficient workspace.

8. Troubleshooting Common Pinewood Derby Car Problems: Identifying and Resolving Issues

Even with careful planning and execution, you may encounter problems during the building process. Here are some common issues and how to resolve them:

8.1. Car Is Too Heavy: Reducing Weight Without Sacrificing Performance

- Identify Excess Weight: Identify areas where you can remove excess weight without sacrificing performance.

- Remove Material: Use a wood file, rasp, or sandpaper to remove material from these areas.

- Consider Lighter Materials: Consider using lighter materials for non-essential components.

Reducing weight is often necessary to meet the weight limit. Focus on removing material from areas that won’t impact performance.

8.2. Car Veers to One Side: Correcting Axle Alignment Issues

- Check Axle Alignment: Use an axle alignment tool to check the axle alignment.

- Adjust Axles: Use pliers or an axle bending tool to make slight adjustments to the axle alignment.

- Re-Test: Re-test the car after each adjustment to evaluate the results.

Axle alignment issues are a common cause of cars veering to one side. Take your time and make small adjustments until the car tracks straight and true.

8.3. Wheels Are Not Spinning Freely: Addressing Friction Problems

- Check for Obstructions: Check the wheels and axles for any obstructions or debris.

- Re-Lubricate: Re-lubricate the axles with graphite powder.

- Polish Axles: Polish the axles to a smooth, mirror-like finish.

Friction problems can significantly slow down your car. Address any obstructions, re-lubricate the axles, and polish the axles to minimize friction. CARS.EDU.VN recommends using a high-quality polishing compound.

8.4. Car Is Unstable and Wobbles: Improving Stability and Balance

- Lower Center of Gravity: Lower the car’s center of gravity by adding weight to the bottom of the car.

- Adjust Weight Distribution: Adjust the weight distribution to improve stability and balance.

- Check Axle Alignment: Check the axle alignment to ensure the wheels are tracking straight and true.

Instability and wobbling can significantly impact performance. Focus on lowering the center of gravity, adjusting weight distribution, and ensuring proper axle alignment.

9. Showcasing Your Pinewood Derby Car: Presentation and Display

After all your hard work, it’s time to showcase your Pinewood Derby car. Here are some tips for presentation and display:

9.1. Painting and Finishing Techniques: Adding Visual Appeal

- Prepare Surface: Prepare the car’s surface by sanding it smooth and applying a primer.

- Apply Paint: Apply several thin coats of paint, allowing each coat to dry completely before applying the next.

- Add Details: Add details such as stripes, decals, or custom graphics to enhance the car’s visual appeal.

- Apply Clear Coat: Apply a clear coat to protect the paint and give the car a glossy finish.

Painting and finishing techniques can significantly enhance the visual appeal of your Pinewood Derby car. Take your time and pay attention to detail to achieve a professional-looking finish.

9.2. Adding Decals and Stickers: Personalizing Your Car

- Choose Decals: Choose decals and stickers that reflect your personality and style.

- Apply Decals: Apply the decals carefully, following the manufacturer’s instructions.

- Seal Decals: Seal the decals with a clear coat to protect them and prevent them from peeling.

Decals and stickers are a great way to personalize your Pinewood Derby car and make it stand out from the crowd.

9.3. Creating a Display Stand: Showcasing Your Craftsmanship

- Choose Materials: Choose materials such as wood, plastic, or metal to create a display stand.

- Design Stand: Design a stand that complements the car’s design and showcases its craftsmanship.

- Assemble Stand: Assemble the stand carefully, ensuring it is stable and secure.

A display stand is a great way to showcase your Pinewood Derby car and protect it from damage.

9.4. Documenting Your Building Process: Sharing Your Journey and Inspiring Others

- Take Photos: Take photos of each step of the building process.

- Write a Journal: Write a journal documenting your experiences, challenges, and successes.

- Share Your Story: Share your story and photos with others online or at the Pinewood Derby event.

Documenting your building process is a great way to share your journey, inspire others, and create lasting memories.

10. Resources and Further Learning: Expanding Your Knowledge

To further expand your knowledge and skills, here are some resources and learning opportunities:

10.1. Official Pinewood Derby Websites and Guides: Reliable Information

- Scouting America: The official website of the Boy Scouts of America, with information on the Pinewood Derby and other Scouting programs (scouting.org)

- Pinewood Derby Resources: Various websites and guides offer tips, tricks, and resources for building fast Pinewood Derby cars.

Official Pinewood Derby websites and guides are a valuable source of reliable information and resources.

10.2. Online Forums and Communities: Connecting with Fellow Builders

- Pinewood Derby Forums: Online forums and communities where you can connect with fellow builders, ask questions, and share tips and experiences.

Online forums and communities are a great way to connect with fellow builders, learn from their experiences, and get advice and support.

10.3. Books and Publications on Pinewood Derby Cars: In-Depth Knowledge

- Pinewood Derby Books: Books and publications that provide in-depth knowledge on Pinewood Derby car design, construction, and optimization.

Books and publications are a valuable resource for gaining in-depth knowledge on Pinewood Derby cars.

10.4. Workshops and Clinics: Hands-On Learning Experience

- Pinewood Derby Workshops: Workshops and clinics where you can learn hands-on skills and techniques from experienced builders.

Workshops and clinics offer a valuable hands-on learning experience and can help you improve your skills and knowledge.

CARS.EDU.VN encourages you to explore these resources and continue learning about Pinewood Derby cars.

FAQ: Your Pinewood Derby Car Questions Answered

Here are some frequently asked questions about building Pinewood Derby cars:

-

What is the ideal weight for a Pinewood Derby car?

The ideal weight is usually the maximum allowed weight, typically 5 ounces (141.75 grams).

-

What is the best lubricant for Pinewood Derby axles?

Graphite powder is the most commonly used and effective lubricant.

-

How important is axle alignment?

Axle alignment is crucial for minimizing friction and ensuring straight tracking.

-

What is the best shape for a Pinewood Derby car?

Aerodynamic shapes like wedges or arrows are often effective.

-

Where should I place the weight on my Pinewood Derby car?

Concentrating weight towards the rear of the car is generally recommended.

-

How can I make my Pinewood Derby car faster?

Minimize friction by polishing axles, lubricating wheels, and optimizing weight distribution.

-

What tools do I need to build a Pinewood Derby car?

Basic tools include a saw, sandpaper, drill, and file. Power tools can enhance precision.

-

How do I prepare the wheels for a Pinewood Derby car?

Remove imperfections, polish to a smooth finish, and lubricate with graphite.

-

Is it important to follow the rules of the Pinewood Derby?

Yes, following the rules is essential for fair competition and to avoid disqualification.

-

Where can I find more information and resources about Pinewood Derby cars?

Official Pinewood Derby websites, online forums, books, and workshops are valuable resources.

CARS.EDU.VN provides comprehensive information and resources on automotive craftsmanship.

As you embark on your Pinewood Derby car building journey, remember that it’s not just about the race. It’s about the fun, the learning, and the memories you create along the way. CARS.EDU.VN hopes this guide has inspired you to build a fast, visually appealing, and safe Pinewood Derby car.

For more in-depth guides, expert advice, and the latest automotive trends, visit CARS.EDU.VN today. And if you’re facing car troubles or seeking reliable maintenance tips, don’t hesitate to reach out to us at 456 Auto Drive, Anytown, CA 90210, United States, or connect via Whatsapp: +1 555-123-4567. Let CARS.EDU.VN be your trusted partner on the road to automotive excellence. Don’t forget to visit our website: cars.edu.vn.