Building a simple mousetrap car is a fun and educational project. CARS.EDU.VN offers a comprehensive guide, showcasing innovative methods and time-tested strategies to construct a successful vehicle. Discover how to maximize your mousetrap car’s distance. This detailed resource also covers energy conversion, potential energy, and propulsion systems.

1. Understanding the Mousetrap Car Challenge

The mousetrap car project is a classic STEM challenge that encourages students and hobbyists to explore fundamental physics principles. The goal is to design and build a vehicle powered solely by the energy of a standard mousetrap. This project isn’t just about building a car; it’s about understanding how energy is stored, transferred, and used to create motion.

1.1. The Core Principles

At the heart of the mousetrap car lies the concept of energy conversion. The mousetrap stores potential energy when it’s set. Releasing the trap converts this potential energy into kinetic energy, which then propels the car forward. Key principles include:

- Potential Energy: The energy stored in the mousetrap spring when it’s set.

- Kinetic Energy: The energy of motion, which is used to turn the wheels of the car.

- Friction: A force that opposes motion, which must be minimized to maximize distance.

- Torque: The rotational force that turns the wheels, which must be carefully managed for optimal performance.

1.2. Setting Realistic Goals

Before diving into the construction process, it’s essential to set realistic goals. Consider the available materials, the project timeline, and the specific requirements of the assignment. Common goals include:

- Distance: How far the car can travel on a single release of the mousetrap.

- Speed: How quickly the car can cover a certain distance.

- Accuracy: How consistently the car can travel in a straight line.

- Cost-Effectiveness: Building a car using inexpensive and readily available materials.

2. Gathering Your Supplies: The Essential Components

The success of your mousetrap car hinges on selecting the right materials. Here’s a detailed list of components you’ll need:

2.1. The Mousetrap

The mousetrap is the heart of your project, providing the necessary power to propel the car.

- Type: A standard-sized wooden mousetrap is ideal. Avoid plastic traps, as they may not provide enough force.

- Modification: Consider reinforcing the mousetrap base with additional wood or glue to prevent it from breaking under stress.

- Placement: Experiment with different mounting positions to optimize the transfer of energy to the drive axle.

2.2. The Chassis

The chassis serves as the foundation of your car, providing a stable platform for all other components.

- Material: Lightweight yet sturdy materials like balsa wood, foam board, or thin plywood work well.

- Shape: A long, narrow chassis tends to perform better, as it reduces weight and aerodynamic drag.

- Dimensions: A length of 12-18 inches and a width of 3-4 inches is a good starting point.

2.3. The Wheels

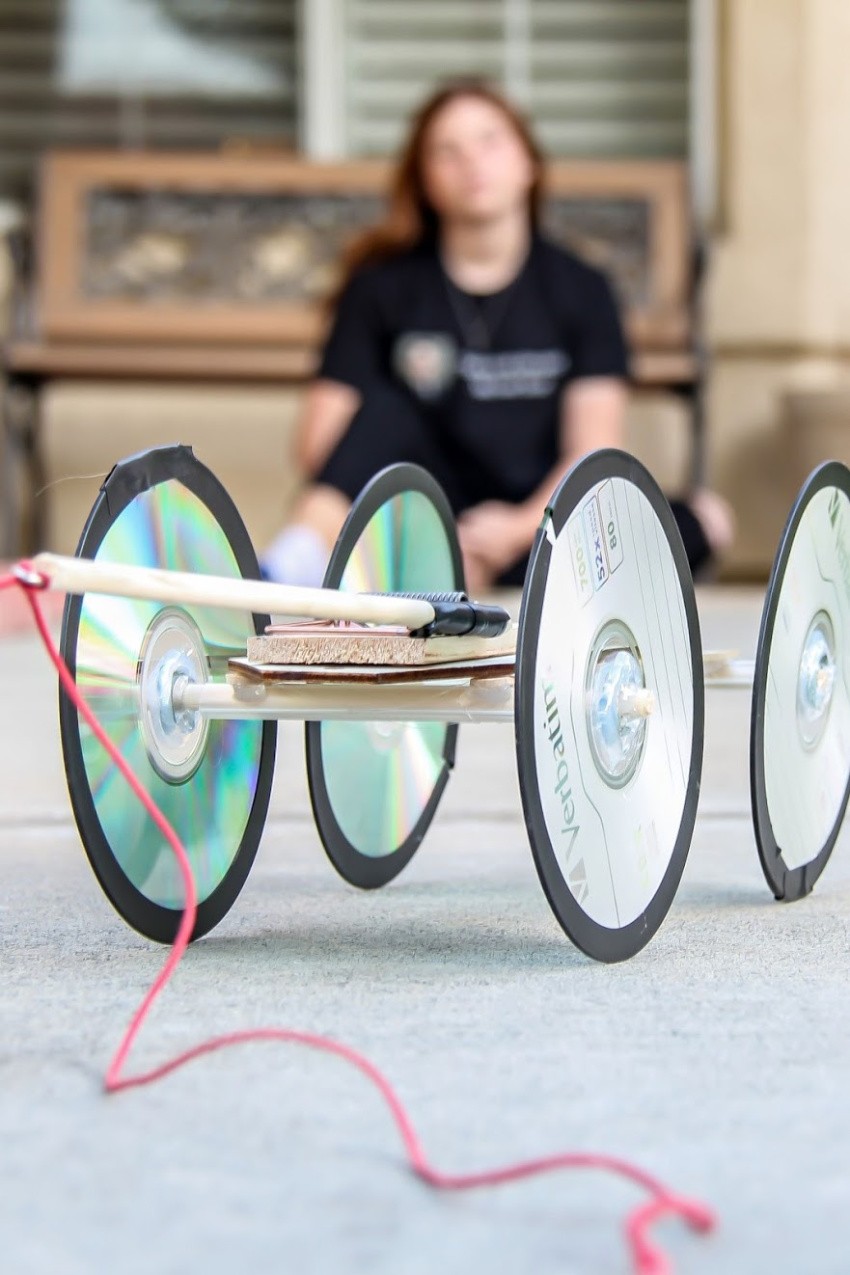

The wheels are crucial for converting rotational motion into linear motion.

- Size: Experiment with different wheel sizes to find the optimal balance between speed and distance. Larger wheels cover more ground per rotation but require more force to turn.

- Material: CD’s or DVD’s offer a good balance of weight and size. Other options include plastic lids, cardboard circles, or even custom-made wheels from wood or foam.

- Attachment: Securely attach the wheels to the axles using glue, tape, or small screws.

Mousetrap car with CD wheels

Mousetrap car with CD wheels

2.4. The Axles

The axles connect the wheels to the chassis, allowing them to rotate freely.

- Material: Wooden dowels, metal rods, or even sturdy plastic straws can be used as axles.

- Diameter: Choose a diameter that fits snugly inside the wheel hubs and allows for smooth rotation.

- Support: Use straws or small tubes as bearings to reduce friction between the axles and the chassis.

2.5. The Lever Arm

The lever arm is responsible for transferring the force of the mousetrap to the drive axle.

- Material: A lightweight but strong material like balsa wood, a wooden skewer, or a metal rod is ideal.

- Length: Experiment with different lever arm lengths to adjust the torque and speed of the car. A longer lever arm provides more torque but less speed, while a shorter lever arm provides more speed but less torque.

- Attachment: Securely attach the lever arm to the mousetrap’s snapper arm using glue, tape, or a small screw.

2.6. The String or Cord

The string or cord connects the lever arm to the drive axle, transmitting the force that turns the wheels.

- Material: A strong, lightweight string like fishing line, dental floss, or thin twine works well.

- Length: The length of the string should be adjusted so that the mousetrap is fully triggered before the car reaches its maximum distance.

- Attachment: Securely attach the string to the lever arm and the drive axle using knots, glue, or tape.

2.7. Other Essential Tools and Supplies

- Hot glue gun and glue sticks

- Scissors or a craft knife

- Ruler or measuring tape

- Pencil or marker

- Sandpaper (for smoothing rough edges)

- Lubricant (such as WD-40 or silicone spray) to reduce friction

- Electrical tape for securing components

3. Step-by-Step Guide to Building Your Mousetrap Car

With your supplies gathered, it’s time to start building your mousetrap car. Follow these step-by-step instructions:

3.1. Preparing the Chassis

- Cut the chassis: Use scissors or a craft knife to cut the chassis to the desired length and width.

- Smooth the edges: Sand any rough edges to prevent splinters and ensure a smooth surface.

- Mark the axle positions: Use a ruler and pencil to mark the locations for the front and rear axles. Ensure that the axles are aligned and perpendicular to the length of the chassis.

- Attach the axle supports: Glue or tape the straws or small tubes to the chassis at the marked axle positions. These will serve as bearings for the axles.

3.2. Assembling the Axles and Wheels

- Prepare the axles: Cut the axles to the appropriate length, ensuring that they extend slightly beyond the width of the wheels.

- Attach the wheels: Securely attach the wheels to the axles using glue, tape, or small screws. Make sure the wheels are centered on the axles and rotate freely.

- Insert the axles: Slide the axles through the axle supports on the chassis. Ensure that the wheels rotate smoothly without binding.

- Secure the axles: Use washers or small pieces of tape to prevent the axles from sliding out of the supports.

3.3. Mounting the Mousetrap

- Position the mousetrap: Experiment with different mounting positions to optimize the transfer of energy to the drive axle. A position near the rear axle often works well.

- Secure the mousetrap: Glue or tape the mousetrap to the chassis. Ensure that it is firmly attached and does not wobble.

- Attach the lever arm: Securely attach the lever arm to the mousetrap’s snapper arm using glue, tape, or a small screw.

- Adjust the lever arm length: Experiment with different lever arm lengths to adjust the torque and speed of the car.

3.4. Connecting the Lever Arm to the Drive Axle

- Attach the string: Securely attach one end of the string to the end of the lever arm using a knot, glue, or tape.

- Wrap the string around the axle: Wrap the string around the drive axle several times, ensuring that it is snug but not too tight.

- Secure the string to the axle: Securely attach the other end of the string to the drive axle using a knot, glue, or tape.

- Adjust the string length: Adjust the length of the string so that the mousetrap is fully triggered before the car reaches its maximum distance.

3.5. Fine-Tuning and Testing

- Test the car: Place the car on a smooth, flat surface and release the mousetrap. Observe how the car moves and identify any problems.

- Adjust the wheel alignment: If the car veers to one side, adjust the alignment of the wheels.

- Lubricate the axles: Apply a small amount of lubricant to the axles to reduce friction and improve performance.

- Adjust the lever arm length: Experiment with different lever arm lengths to optimize the car’s speed and distance.

- Adjust the string tension: Adjust the tension of the string to optimize the transfer of energy from the mousetrap to the drive axle.

- Add weight: Experiment with adding weight to different parts of the car to improve traction and stability.

4. Advanced Techniques for Maximizing Performance

Once you’ve mastered the basics, you can explore advanced techniques to take your mousetrap car to the next level.

4.1. Optimizing Wheel Size and Gear Ratios

The size of the wheels and the gear ratio between the lever arm and the drive axle play a crucial role in determining the car’s speed and distance.

- Larger Wheels: Larger wheels cover more ground per rotation but require more force to turn. They are best suited for cars designed to travel long distances.

- Smaller Wheels: Smaller wheels require less force to turn but cover less ground per rotation. They are best suited for cars designed for speed.

- Gear Ratios: The gear ratio is the ratio between the number of rotations of the lever arm and the number of rotations of the drive axle. A higher gear ratio provides more torque but less speed, while a lower gear ratio provides more speed but less torque.

4.2. Minimizing Friction

Friction is the enemy of the mousetrap car. It slows the car down and reduces the distance it can travel.

- Use Low-Friction Materials: Choose materials with low coefficients of friction for the axles, wheels, and chassis.

- Lubricate Moving Parts: Apply a small amount of lubricant to the axles and other moving parts to reduce friction.

- Align the Wheels: Ensure that the wheels are properly aligned and do not rub against the chassis or other components.

- Reduce Weight: Minimize the weight of the car to reduce the amount of force required to overcome friction.

4.3. Improving Traction

Traction is the force that allows the wheels to grip the surface and propel the car forward.

- Use High-Traction Tires: Choose tires with a high coefficient of friction to maximize traction.

- Add Weight: Add weight to the drive wheels to increase the amount of force pressing them against the surface.

- Clean the Tires: Keep the tires clean and free of dirt and debris to maintain optimal traction.

4.4. Aerodynamic Considerations

At higher speeds, aerodynamic drag can become a significant factor.

- Streamline the Chassis: Design the chassis with a streamlined shape to reduce aerodynamic drag.

- Minimize Surface Area: Reduce the surface area of the car to minimize the amount of air resistance.

- Use Lightweight Materials: Use lightweight materials to reduce the overall weight of the car and improve its acceleration.

5. Troubleshooting Common Problems

Even with careful planning and construction, you may encounter problems with your mousetrap car. Here are some common issues and how to fix them:

5.1. The Car Doesn’t Move

- Check the mousetrap: Ensure that the mousetrap is properly set and that the snapper arm is moving freely.

- Check the string: Ensure that the string is properly attached to the lever arm and the drive axle, and that it is not tangled or broken.

- Check the wheels: Ensure that the wheels are properly attached to the axles and that they are rotating freely.

- Check for friction: Ensure that there is no excessive friction between the axles and the chassis, or between the wheels and the surface.

5.2. The Car Moves Slowly

- Adjust the lever arm length: Experiment with different lever arm lengths to optimize the car’s speed and distance.

- Adjust the gear ratio: Experiment with different gear ratios to optimize the car’s speed and distance.

- Reduce friction: Apply lubricant to the axles and other moving parts to reduce friction.

- Add weight: Add weight to the drive wheels to increase traction.

5.3. The Car Veers to One Side

- Adjust the wheel alignment: Adjust the alignment of the wheels to ensure that they are parallel to each other.

- Check for uneven friction: Ensure that there is no uneven friction between the wheels and the surface.

- Check for a bent axle: Ensure that the axles are straight and not bent.

5.4. The String Slips on the Axle

- Use a rougher string: Use a string with a rougher surface to increase friction between the string and the axle.

- Apply adhesive to the axle: Apply a small amount of adhesive to the axle to increase friction between the string and the axle.

- Increase the string tension: Increase the tension of the string to increase friction between the string and the axle.

6. The Science Behind the Mousetrap Car

The mousetrap car is a great way to learn about physics concepts such as energy, motion, and friction.

6.1. Newton’s Laws of Motion

Newton’s laws of motion are fundamental to understanding how the mousetrap car works.

- First Law (Inertia): An object at rest stays at rest, and an object in motion stays in motion with the same speed and in the same direction unless acted upon by a force.

- Second Law (F=ma): The acceleration of an object is directly proportional to the net force acting on it and inversely proportional to its mass.

- Third Law (Action-Reaction): For every action, there is an equal and opposite reaction.

6.2. Energy Conservation

The mousetrap car demonstrates the principle of energy conservation.

- Potential Energy: The energy stored in the mousetrap spring when it’s set.

- Kinetic Energy: The energy of motion, which is used to turn the wheels of the car.

- Energy Conversion: The process of converting potential energy into kinetic energy.

6.3. Friction and Efficiency

Friction is a force that opposes motion and reduces the efficiency of the mousetrap car.

- Coefficient of Friction: A measure of the amount of friction between two surfaces.

- Reducing Friction: Using low-friction materials, lubricating moving parts, and aligning the wheels.

- Efficiency: The ratio of the amount of energy used to propel the car to the amount of energy stored in the mousetrap.

7. Safety Precautions

When building and testing your mousetrap car, it’s important to take safety precautions.

- Wear safety glasses: Protect your eyes from flying debris.

- Use caution with sharp tools: Be careful when using scissors, craft knives, and other sharp tools.

- Supervise children: Children should be supervised by an adult when building and testing mousetrap cars.

- Test in a safe area: Test the car in a clear, open area away from obstacles and people.

8. Real-World Applications of Mousetrap Car Principles

The principles behind the mousetrap car aren’t just for classroom projects; they have real-world applications in engineering and technology.

8.1. Automotive Engineering

- Energy Efficiency: Automakers constantly seek ways to improve energy efficiency, similar to optimizing a mousetrap car for maximum distance.

- Power Transmission: The mousetrap car’s lever and string system demonstrates basic power transmission principles used in vehicle drivetrains.

- Friction Reduction: Engineers work to minimize friction in engines and other components to improve performance and fuel economy.

8.2. Robotics

- Small-Scale Propulsion: The concepts of using stored energy for propulsion are relevant in designing small robots.

- Mechanical Design: The design challenges in a mousetrap car mirror those in creating functional and efficient robotic systems.

- Energy Storage: Exploring alternative energy storage methods for robots draws inspiration from simple models like the mousetrap car.

8.3. Sustainable Transportation

- Alternative Energy Sources: The mousetrap car exemplifies using non-traditional energy sources to achieve movement.

- Lightweight Design: Building lightweight vehicles is key to enhancing fuel efficiency and reducing environmental impact.

- Innovative Propulsion Systems: Engineers look to creative propulsion systems to develop sustainable transportation solutions.

9. Incorporating Digital Technology

Enhance your mousetrap car project by integrating digital technology for analysis and improvement.

9.1. Data Logging

- Sensors: Attach sensors to measure speed, distance, and acceleration.

- Microcontrollers: Use Arduino or Raspberry Pi to record and analyze data in real-time.

- Performance Tracking: Log data to identify areas for improvement and track progress.

9.2. 3D Printing

- Custom Parts: Design and print custom wheels, chassis components, and lever systems.

- Prototyping: Quickly create and test different designs to optimize performance.

- Material Experimentation: Explore various 3D printing materials to achieve the perfect balance of weight and strength.

9.3. Simulation Software

- Design Testing: Use software to simulate performance before physical construction.

- Optimization: Test different designs and parameters to find the ideal configuration.

- Predictive Analysis: Analyze simulation results to predict real-world performance.

10. Mousetrap Car Competitions and Clubs

Participate in mousetrap car competitions and clubs to test your skills and learn from others.

10.1. Competition Rules and Guidelines

- Distance Challenges: Design a car to travel the farthest distance.

- Speed Races: Build a car for maximum speed over a short distance.

- Accuracy Events: Create a car to hit a specific target.

- Design Judging: Get evaluated on creativity, craftsmanship, and engineering principles.

10.2. Forming or Joining a Club

- Collaborative Projects: Work together on building and improving mousetrap cars.

- Knowledge Sharing: Exchange tips, techniques, and best practices.

- Organized Events: Host competitions, workshops, and demonstrations.

10.3. Online Communities

- Forums: Participate in online discussions, share your designs, and ask questions.

- Social Media: Connect with other enthusiasts and showcase your projects.

- Video Tutorials: Watch and share videos on building, testing, and optimizing mousetrap cars.

11. Inspiring Examples and Case Studies

Explore success stories to inspire your mousetrap car design and optimization efforts.

11.1. Record-Breaking Designs

- High-Distance Cars: Analyze design features, materials, and techniques used in cars that achieved record distances.

- Fastest Speed Cars: Study the lightweight construction and efficient energy transfer systems of the speediest models.

- Innovative Approaches: Examine creative and unconventional designs for unique insights.

11.2. Competition Winners

- Design Analysis: Deconstruct the winning designs from various competitions.

- Material Choices: Evaluate the selection of materials in top-performing cars.

- Optimization Strategies: Review the adjustments and fine-tuning that led to victory.

11.3. Student Projects

- Learning Experiences: Learn from successful student projects and their problem-solving processes.

- Iterative Improvements: Observe how students refined their designs through testing and feedback.

- Creative Solutions: Discover ingenious solutions to common challenges in building mousetrap cars.

12. Frequently Asked Questions (FAQ)

Have questions about building your mousetrap car? Here are some frequently asked questions:

- What is the best material for the chassis? Lightweight yet sturdy materials like balsa wood or foam board are ideal.

- What size wheels should I use? Experiment with different wheel sizes to find the optimal balance between speed and distance.

- How long should the lever arm be? Experiment with different lever arm lengths to adjust the torque and speed of the car.

- What type of string should I use? A strong, lightweight string like fishing line or dental floss works well.

- How can I reduce friction? Use low-friction materials, lubricate moving parts, and align the wheels.

- How can I improve traction? Use high-traction tires and add weight to the drive wheels.

- What if my car veers to one side? Adjust the wheel alignment and check for uneven friction.

- What if the string slips on the axle? Use a rougher string or apply adhesive to the axle.

- How can I use digital technology to improve my car? Use sensors to measure performance, 3D print custom parts, and use simulation software to test designs.

- Where can I find mousetrap car competitions and clubs? Search online for local and national competitions, and consider forming or joining a club at your school or in your community.

13. The Future of Mousetrap Car Technology

The mousetrap car may seem like a simple project, but it has the potential to inspire future innovations.

13.1. Advanced Materials

- Composites: Using advanced composite materials to create lightweight and strong chassis components.

- Nanomaterials: Incorporating nanomaterials to reduce friction and improve energy transfer.

- Smart Materials: Developing materials that can adapt and optimize their properties based on changing conditions.

13.2. Energy Storage

- Improved Springs: Designing more efficient and powerful mousetrap springs.

- Alternative Mechanisms: Exploring other energy storage mechanisms, such as rubber bands or compressed air.

- Hybrid Systems: Combining multiple energy sources to improve performance and reliability.

13.3. Control Systems

- Autonomous Navigation: Developing control systems that allow the car to navigate autonomously.

- Adaptive Control: Creating systems that can adjust the car’s performance based on changing conditions.

- Remote Control: Implementing remote control systems for enhanced maneuverability and control.

14. Resources for Further Learning

Expand your knowledge with these resources to delve deeper into the world of mousetrap cars.

14.1. Books and Publications

- “The Art of the Mousetrap Car” by [Author Name]: A comprehensive guide to design, construction, and optimization.

- “Mousetrap Cars: A STEM Approach” by [Author Name]: An educational resource exploring the science behind mousetrap cars.

- “Popular Mechanics” magazine: Features articles on building and improving mousetrap cars.

- “Make” magazine: Offers innovative projects and ideas for mousetrap car enthusiasts.

14.2. Online Courses and Tutorials

- Coursera: Offers courses on mechanics, physics, and engineering principles relevant to mousetrap cars.

- Udemy: Provides tutorials on building and optimizing mousetrap cars.

- Instructables: Features detailed guides and projects shared by makers and enthusiasts.

- YouTube: Hosts numerous channels with tutorials, demonstrations, and tips for mousetrap car building.

14.3. Community Forums and Websites

- Science Olympiad: A platform for students to compete and share their mousetrap car designs.

- All About Circuits: A forum for discussing electronics and engineering projects.

- Reddit: Subreddits dedicated to STEM projects and mousetrap cars.

- Hackaday: A website featuring creative and innovative projects from the maker community.

15. CARS.EDU.VN: Your Partner in Automotive Knowledge

At CARS.EDU.VN, we understand the challenges you face in finding reliable automotive services and information. Whether you’re seeking detailed car reviews, maintenance tips, or expert repair advice, we’re here to help.

- Expert Advice: Access a wealth of articles and guides from seasoned automotive professionals.

- Comprehensive Reviews: Get in-depth analyses of the latest car models, performance metrics, and safety features.

- Maintenance and Repair Guides: Follow easy-to-understand guides for routine maintenance and troubleshooting common issues.

If you’re struggling to find reputable repair services, need help with car selection, or want to stay updated on automotive technology, CARS.EDU.VN is your go-to resource.

Visit CARS.EDU.VN today to explore our extensive library of automotive information and discover how we can assist you with all your car-related needs.

Address: 456 Auto Drive, Anytown, CA 90210, United States

WhatsApp: +1 555-123-4567

Website: CARS.EDU.VN

Unlock the full potential of your automotive journey with CARS.EDU.VN. From expert advice to comprehensive guides, we’re here to support you every step of the way. Start exploring now and elevate your driving experience.

Building a simple mousetrap car is a rewarding project that combines science, engineering, and creativity. By following the steps outlined in this guide and exploring the resources available at cars.edu.vn, you can create a high-performance vehicle that will impress your friends, teachers, and fellow enthusiasts. So gather your supplies, unleash your inner engineer, and get ready to build the ultimate mousetrap car.