What Is A Cvt Transmission In A Car? It’s a type of automatic transmission offering seamless gear ratio changes. At CARS.EDU.VN, we provide comprehensive details on continuously variable transmissions, revealing how they enhance fuel efficiency and driving experience. Explore our site for more automotive insights, automatic transmission benefits and continuously variable transmission advantages.

1. Understanding Continuously Variable Transmissions (CVT)

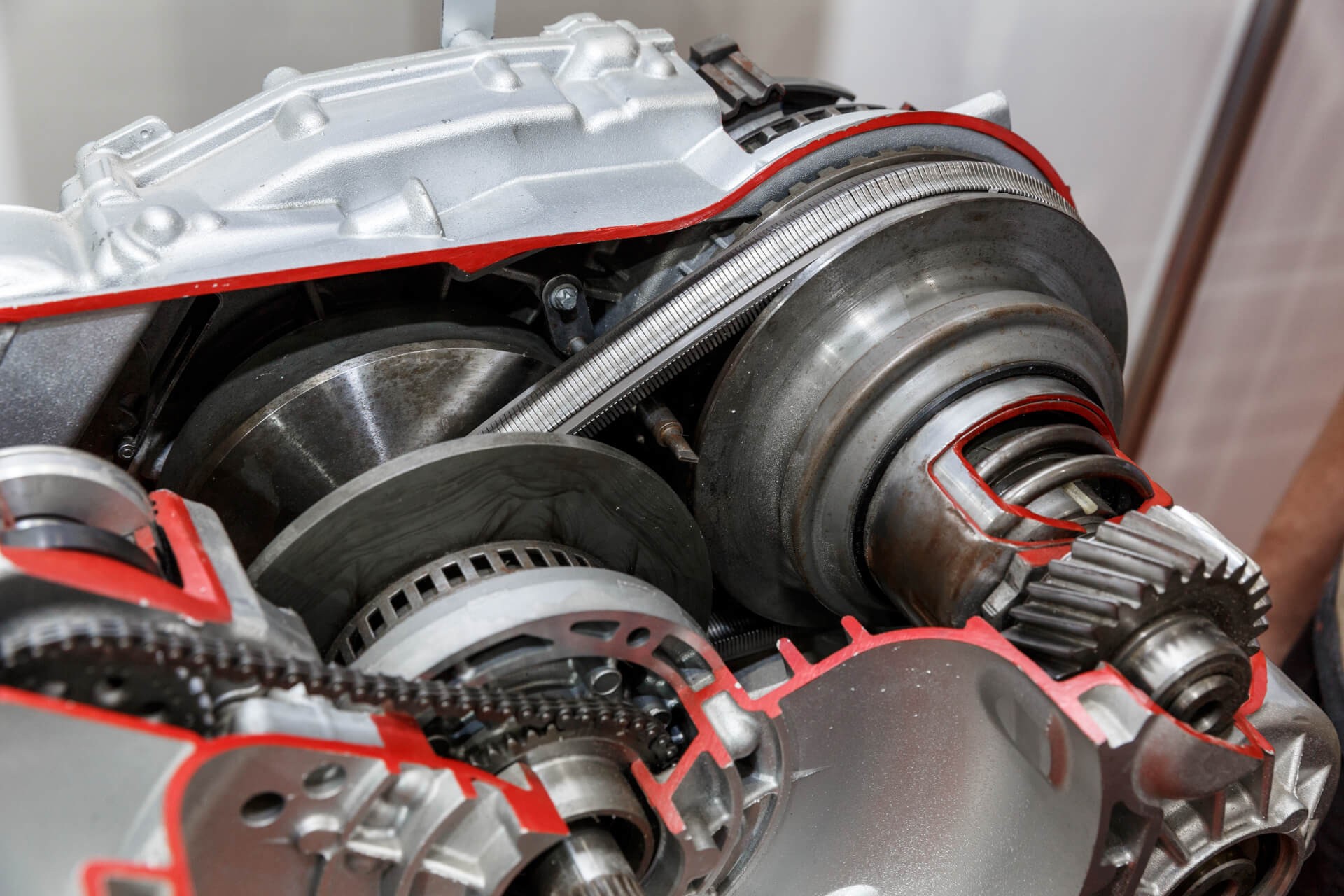

A continuously variable transmission (CVT) is a type of automatic transmission that uses a belt, pulleys, or chains to transfer power from the engine to the drivetrain. Unlike traditional automatic transmissions with fixed gears, a CVT offers an infinite range of gear ratios. This allows the engine to consistently operate at its most efficient revolutions per minute (RPM), optimizing performance under various driving conditions. CVTs are becoming increasingly popular due to their ability to enhance fuel economy and provide a smooth driving experience. According to a report by the U.S. Environmental Protection Agency (EPA), vehicles equipped with CVTs often achieve better gas mileage compared to those with traditional transmissions.

1.1. The Core Concept of CVT Gearboxes

The core concept of a CVT gearbox is its ability to provide a seamless and continuous range of gear ratios. Traditional transmissions have a limited number of fixed gears, which can cause noticeable shifts and interruptions in power delivery. In contrast, a CVT uses a system of belts and pulleys to adjust the gear ratio fluidly, ensuring the engine operates at its optimal RPM for any given speed. This design leads to increased efficiency and a smoother driving experience. A study by the Society of Automotive Engineers (SAE) found that CVTs can improve fuel efficiency by up to 6% compared to conventional automatic transmissions.

1.2. Historical Development of CVTs

The history of CVTs dates back to the late 19th century, with early concepts and prototypes developed for various applications. However, it wasn’t until the mid-20th century that CVTs began to see practical use in automotive applications. One of the early pioneers in CVT technology was DAF, a Dutch automaker, which introduced the Variomatic CVT system in its cars in the late 1950s. Over the years, CVT technology has evolved significantly, with advancements in materials, control systems, and overall design. Modern CVTs are more reliable, efficient, and capable of handling higher torque loads than their early counterparts. According to a report by Automotive Engineering International, ongoing research and development efforts are focused on further improving the performance and durability of CVTs.

2. How a CVT Works: The Mechanics Explained

The most common type of CVT is pulley-based, consisting of a metal belt or chain that runs between two variable-diameter pulleys. One pulley is connected to the engine’s crankshaft, while the other is connected to the wheels. The effective diameter of these pulleys can be adjusted, allowing the CVT to provide a wide range of gear ratios. As the driver accelerates, the control system monitors parameters such as engine speed, vehicle speed, and load, and adjusts the positions of the pulley halves. This alters the gear ratio, ensuring the engine operates at its most efficient RPM.

2.1. Pulley Systems in CVTs

The pulley system in a CVT is the heart of its operation. Each pulley consists of two cone-shaped halves that can move closer together or farther apart. As these halves move, they change the effective diameter of the pulley. When one pulley’s diameter increases, the other pulley’s diameter decreases, creating a continuous range of gear ratios. The belt or chain that connects the two pulleys must be durable and capable of withstanding high tension and friction. Modern CVTs often use metal belts made of high-strength steel to ensure longevity and reliability. According to HowStuffWorks, the precise control of the pulley system is essential for achieving optimal performance and efficiency in a CVT.

2.2. Belt and Chain Mechanisms

The belt or chain mechanism in a CVT plays a critical role in transferring power between the pulleys. Early CVTs often used rubber belts, but these were prone to slippage and wear, especially under high loads. Modern CVTs typically use metal belts or chains that are designed to handle higher torque and provide better durability. These metal belts are often constructed from multiple layers of steel bands, which are held together by a series of interlocking elements. The design of the belt or chain must allow it to bend and flex as it moves around the pulleys, while also maintaining its strength and integrity. A study by SAE International highlighted the importance of advanced materials and manufacturing techniques in improving the performance and reliability of CVT belts and chains.

2.3. The Role of the Control System

The control system in a CVT is responsible for managing the positions of the pulleys and maintaining the optimal gear ratio for any given driving condition. This system uses a variety of sensors to monitor engine speed, vehicle speed, throttle position, and other parameters. Based on this data, the control system adjusts the hydraulic pressure that controls the movement of the pulley halves. Modern CVTs often use sophisticated electronic control units (ECUs) to optimize performance and efficiency. These ECUs can implement complex control algorithms that take into account a wide range of factors, such as driver behavior, road conditions, and vehicle load. According to a report by Bosch, advanced control systems are essential for maximizing the benefits of CVT technology.

3. The Driving Experience with a CVT

Driving a car with a CVT is a unique experience compared to driving a car with a traditional automatic or manual transmission. One of the most noticeable differences is the absence of distinct gear shifts. Instead of feeling the car jerk or lurch as it changes gears, the CVT provides a smooth and seamless acceleration. This can make the driving experience feel more refined and comfortable, especially in urban traffic where frequent acceleration and deceleration are common. However, some drivers may find the lack of distinct gear shifts to be less engaging or even boring. The engine sound can also be different, as the CVT often allows the engine to operate at a constant RPM, which can result in a droning noise.

3.1. Smoothness and Seamless Acceleration

The smoothness and seamless acceleration provided by a CVT are among its most appealing features. Because the CVT can continuously adjust the gear ratio, there are no interruptions in power delivery. This results in a smooth and linear acceleration, without the jerks and pauses that are typical of traditional transmissions. This can be particularly beneficial in situations where smooth acceleration is important, such as merging onto a highway or navigating stop-and-go traffic. According to a review by Car and Driver, the smooth acceleration of a CVT can make driving more relaxing and less tiring.

3.2. Engine Sound and RPM Management

The engine sound and RPM management in a CVT can be quite different from that of a traditional transmission. In a traditional transmission, the engine RPM will typically rise and fall as the car accelerates through the gears. In contrast, a CVT often allows the engine to operate at a constant RPM, regardless of the vehicle’s speed. This can result in a droning noise that some drivers find annoying. However, this constant RPM management also allows the engine to operate at its most efficient point, which can improve fuel economy. A study by Consumer Reports found that some drivers dislike the engine sound of CVTs, while others appreciate the fuel efficiency benefits.

3.3. Responsiveness and Driver Engagement

The responsiveness and driver engagement of a CVT can be a point of contention for some drivers. While the smooth and seamless acceleration is appreciated by many, some drivers miss the feeling of control and engagement that comes with shifting gears in a traditional transmission. CVTs can sometimes feel less responsive than traditional transmissions, especially when trying to accelerate quickly from a standstill. However, modern CVTs often include features such as simulated gear shifts or paddle shifters to provide a more engaging driving experience. According to a survey by Edmunds, driver preferences for CVT responsiveness and engagement vary widely, with some drivers preferring the simplicity and smoothness of the CVT, while others prefer the more tactile feel of a traditional transmission.

4. Advantages of Continuously Variable Transmissions

CVTs offer several advantages over traditional automatic and manual transmissions. These advantages include improved fuel efficiency, a smoother driving experience, and a more compact and lightweight design. As a result, CVTs are becoming increasingly popular in a wide range of vehicles, from compact cars to hybrid and electric vehicles.

4.1. Enhanced Fuel Efficiency

One of the primary advantages of CVTs is their ability to enhance fuel efficiency. By allowing the engine to operate at its most efficient RPM, CVTs can minimize fuel consumption and reduce emissions. This is particularly noticeable in urban driving conditions, where frequent acceleration and deceleration can take a toll on fuel economy. According to the U.S. Department of Energy, CVTs can improve fuel efficiency by up to 10% compared to traditional automatic transmissions.

4.2. Smoother Ride Quality

CVTs provide a smoother ride quality compared to traditional transmissions, thanks to their seamless and continuous gear ratio changes. The absence of distinct gear shifts eliminates the jerks and lurches that can be common in traditional transmissions. This can make the driving experience more comfortable and relaxing, especially on long trips or in stop-and-go traffic. A review by Motor Trend highlighted the smooth ride quality of CVTs as one of their key advantages.

4.3. Compact and Lightweight Design

CVTs are generally more compact and lightweight than traditional transmissions. This can contribute to improved vehicle handling and fuel economy. The compact design of CVTs also allows them to be easily integrated into a variety of vehicle platforms, including hybrid and electric vehicles. According to a report by AVL, the lightweight design of CVTs can reduce overall vehicle weight, leading to further improvements in fuel efficiency.

5. Disadvantages of CVT Transmissions in Cars

While CVTs offer several advantages, they also have some drawbacks that should be considered. These disadvantages include potential durability issues, higher repair costs, and noise concerns. Understanding these potential issues is essential for making an informed decision about whether a CVT is the right choice for your needs.

5.1. Potential Durability Concerns

One of the primary concerns about CVTs is their potential durability. While modern CVTs are more reliable than their early counterparts, they can still be more prone to failure than traditional transmissions, especially under high stress or heavy use. Proper maintenance, including regular fluid changes, is essential for maximizing the lifespan of a CVT. According to J.D. Power, CVT reliability has improved in recent years, but it remains an area of concern for some consumers.

5.2. Increased Repair Expenses

CVTs can be more expensive to repair or replace than traditional transmissions. This is due to the complexity of the CVT design and the specialized tools and knowledge required to service them. If a CVT fails, it may be more cost-effective to replace the entire transmission rather than attempt to repair individual components. A report by AAA found that CVT repairs can be significantly more expensive than traditional transmission repairs.

5.3. Noise and Vibration Issues

Some drivers complain about the noise and vibration produced by CVTs. The engine’s constant RPM can create a droning sound that some find annoying. CVTs can also produce vibrations, especially during acceleration or at high speeds. These noise and vibration issues can detract from the overall driving experience. According to a survey by Consumer Reports, noise and vibration are among the most common complaints about CVTs.

6. Popular Car Models Featuring CVTs

CVTs are used in a wide range of car models from various manufacturers. Some of the most popular car models that feature CVTs include:

6.1. Nissan Models

Nissan has been a strong proponent of CVT technology, incorporating it into many of their models, including the Altima, Rogue, Sentra, and Versa. Nissan’s CVTs are known for their smooth operation and fuel efficiency. According to Nissan’s official website, their CVTs are designed to provide a seamless and responsive driving experience.

6.2. Honda Models

Honda also uses CVTs in several of their models, including the Civic, Accord, and CR-V. Honda’s CVTs are known for their reliability and performance. A review by Kelley Blue Book praised the smooth and efficient operation of Honda’s CVTs.

6.3. Toyota Models

Toyota incorporates CVTs into many of their hybrid models, including the Prius, Corolla Hybrid, and RAV4 Hybrid. Toyota’s CVTs are designed to maximize fuel efficiency and provide a smooth driving experience. According to Toyota’s official website, their hybrid models with CVTs offer exceptional fuel economy.

6.4. Subaru Models

Subaru is another manufacturer that widely uses CVTs in their vehicles, such as the Impreza, Legacy, Outback, and Forester. Subaru’s CVTs are designed to work in conjunction with their Symmetrical All-Wheel Drive system, providing excellent traction and stability. A review by Edmunds highlighted the smooth and capable performance of Subaru’s CVTs.

| Car Model | Manufacturer | Key Features |

|---|---|---|

| Nissan Altima | Nissan | Smooth operation, fuel efficiency |

| Honda Civic | Honda | Reliability, performance |

| Toyota Prius | Toyota | Maximized fuel efficiency, smooth driving |

| Subaru Impreza | Subaru | Symmetrical All-Wheel Drive, excellent traction |

7. Maintenance Tips for CVT Transmissions

Proper maintenance is crucial for ensuring the longevity and reliability of a CVT. Here are some essential maintenance tips:

7.1. Regular Fluid Replacements

One of the most important maintenance tasks for a CVT is regular fluid replacement. CVT fluid lubricates the internal components of the transmission and helps to keep it cool. Over time, the fluid can degrade and become contaminated, which can lead to increased wear and tear on the transmission. Consult your vehicle’s owner’s manual for the recommended fluid change intervals. According to Valvoline, using the correct type of CVT fluid is essential for optimal performance and protection.

7.2. Inspecting the Transmission for Leaks

Regularly inspect the transmission for leaks. Leaks can indicate a problem with the seals or gaskets, and if left unaddressed, they can lead to low fluid levels and transmission damage. If you notice any leaks, have them repaired promptly by a qualified technician. A report by Mobil emphasized the importance of detecting and repairing transmission leaks to prevent costly damage.

7.3. Avoiding Harsh Driving Conditions

Avoid harsh driving conditions, such as frequent hard acceleration, towing heavy loads, or driving in extreme temperatures. These conditions can put excessive stress on the transmission and shorten its lifespan. Driving in a smooth and controlled manner can help to prolong the life of your CVT. According to Car and Driver, avoiding aggressive driving habits can significantly extend the life of your vehicle’s transmission.

8. Real-World Applications and Use Cases

CVT technology is applied across various vehicle types and driving scenarios, demonstrating its versatility and adaptability.

8.1. Urban Commuting

In urban environments, CVTs shine due to their smooth operation and efficiency in stop-and-go traffic. The seamless transitions and optimized RPMs result in fuel savings and reduced driver fatigue. Traffic Technology International highlights the role of CVTs in improving urban air quality through reduced emissions.

8.2. Hybrid and Electric Vehicles

CVTs are a natural fit for hybrid and electric vehicles, where efficiency is paramount. The ability to maintain optimal engine or motor speed enhances the overall efficiency of the powertrain. Green Car Reports notes that CVTs contribute to the extended range and improved fuel economy of hybrid vehicles.

8.3. High-Performance Vehicles

While often associated with economy cars, CVTs are also finding their way into high-performance vehicles. Advanced control systems and robust designs allow CVTs to handle the increased power and demands of performance driving. Road & Track discusses how some sports cars use CVTs to optimize acceleration and lap times.

9. Future Trends in CVT Technology

The future of CVT technology looks promising, with ongoing research and development efforts focused on improving performance, reliability, and efficiency. Some of the key trends in CVT technology include:

9.1. Enhanced Materials and Designs

Manufacturers are exploring new materials and designs to improve the durability and performance of CVT belts and pulleys. These advancements aim to increase the torque capacity of CVTs and reduce wear and tear. A report by Materials Today highlights the potential of advanced materials in enhancing CVT performance.

9.2. Integration with Advanced Driver-Assistance Systems (ADAS)

CVTs are increasingly being integrated with ADAS to provide a more seamless and efficient driving experience. This integration allows the CVT to anticipate changes in driving conditions and adjust the gear ratio accordingly. Automotive World discusses how ADAS and CVTs are working together to improve vehicle safety and efficiency.

9.3. Artificial Intelligence (AI) and Machine Learning (ML) Applications

AI and ML are being used to optimize the control systems of CVTs, improving their performance and efficiency. These technologies can learn from driver behavior and adapt the CVT’s control strategy to suit individual driving styles. IEEE Spectrum explores the use of AI and ML in optimizing vehicle powertrain systems, including CVTs.

10. Seeking Expert Advice and Services at CARS.EDU.VN

Are you finding it challenging to locate reliable and high-quality auto repair services? Do you lack the necessary knowledge for routine car maintenance to prevent significant breakdowns? Are you unsure about which car type or brand suits your needs and budget? Or perhaps you’re struggling to fix minor car issues yourself? At CARS.EDU.VN, we understand these concerns and offer expert insights and services to address all your automotive needs.

CARS.EDU.VN provides detailed information on car care and repair services, straightforward guides for regular maintenance, comprehensive reviews and comparisons of various car types and brands, and instructions for resolving simple car problems. We also keep you updated on the latest automotive technologies and in-depth car reviews.

Visit CARS.EDU.VN today to explore our resources and discover how we can assist you with your car care and maintenance requirements. For further assistance, visit us at 456 Auto Drive, Anytown, CA 90210, United States. Contact us via WhatsApp at +1 555-123-4567 or through our website CARS.EDU.VN.

Frequently Asked Questions (FAQ)

1. What is a CVT transmission in a car?

A CVT, or continuously variable transmission, is an automatic transmission that provides a seamless range of gear ratios, unlike traditional transmissions with fixed gears.

2. How does a CVT work?

A CVT typically uses a belt and pulley system to adjust the gear ratio continuously, allowing the engine to operate at its most efficient RPM.

3. What are the benefits of a CVT?

CVTs offer improved fuel efficiency, smoother acceleration, and a more compact design compared to traditional transmissions.

4. Are there any drawbacks to using a CVT?

Some potential drawbacks include durability concerns, higher repair costs, and noise or vibration issues.

5. Which car models come with a CVT?

Many car models from manufacturers like Nissan, Honda, Toyota, and Subaru offer CVTs.

6. How can I maintain a CVT to ensure its longevity?

Regular fluid replacements, inspecting for leaks, and avoiding harsh driving conditions are essential for maintaining a CVT.

7. Is a CVT suitable for high-performance vehicles?

Yes, advanced CVTs are now being used in some high-performance vehicles due to their ability to optimize acceleration.

8. What are the future trends in CVT technology?

Future trends include enhanced materials, integration with ADAS, and the use of AI and machine learning to optimize CVT control systems.

9. How does a CVT affect the driving experience?

CVTs provide a smoother driving experience with seamless acceleration, but some drivers may miss the distinct gear shifts of traditional transmissions.

10. Where can I find more information about CVT transmissions and car maintenance?

Visit cars.edu.vn for detailed information on CVT transmissions, car care tips, and expert automotive services.