Your car’s drive belt is a seemingly simple component, but it plays a vital role in keeping everything running smoothly. Often called a serpentine belt or accessory belt, it’s responsible for powering essential systems that you rely on every time you drive. If you’ve ever wondered “What Is A Drive Belt On A Car?” and what it actually does, you’ve come to the right place. This guide will explain everything you need to know about drive belts, their function, maintenance, and what to do if things go wrong.

Understanding the Drive Belt: The Unsung Hero of Your Engine

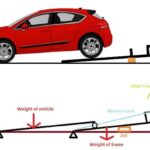

The drive belt is essentially a long, rubber belt that loops around various pulleys in your engine bay. Its primary function is to transfer rotational power from the engine’s crankshaft to several crucial auxiliary components. Think of it as a power connector, ensuring these systems get the energy they need to operate.

What exactly does the drive belt power? Depending on your car’s make and model, it can be connected to a range of accessories, including:

- Air Conditioning Compressor: Keeps you cool in summer by powering the AC system.

- Alternator: Charges your car battery and provides power to the electrical system while the engine is running.

- Power Steering Pump: Makes steering your car easier, especially at low speeds. (Note: Some vehicles use an electric power steering system or a separate belt for this).

- Water Pump: Circulates coolant throughout the engine to prevent overheating.

- Radiator Fan: Draws air through the radiator to help cool the engine, especially when stationary or in slow-moving traffic.

- Air Pump (in some older vehicles): Part of the emissions control system.

Without a functioning drive belt, these systems would fail, leading to a range of problems from discomfort to potential engine damage.

It’s important to distinguish the drive belt from the timing belt (or timing chain). While both are belts in your engine, they have completely different jobs. The timing belt is located inside the engine and synchronizes the crankshaft and camshaft, controlling the engine’s valves. A timing belt failure can cause severe engine damage, whereas a drive belt failure, while inconvenient, is less likely to cause catastrophic internal engine damage.

However, a broken drive belt can still lead to significant issues and even safety concerns, particularly if it affects the power steering or engine cooling.

Types of Drive Belts: V-Belts and Serpentine Belts

Drive belts come in different designs, primarily categorized into two main types:

V-Belts

V-belts are the older style of drive belt, characterized by their trapezoidal or “V” shaped cross-section. They fit into V-shaped grooves in the pulleys. Older vehicles often used multiple V-belts to drive individual accessories.

Advantages of V-Belts:

- Cost-effective: Generally less expensive than serpentine belts.

- Flexible: Can be used in tighter spaces and around smaller pulleys.

Disadvantages of V-Belts:

- Less efficient: More prone to slippage, especially when worn or in wet conditions.

- Shorter lifespan: Typically need replacing more frequently than serpentine belts.

- Require more adjustment: Tension needs to be checked and adjusted periodically.

Serpentine Belts (Ribbed Belts)

Serpentine belts, also known as multi-rib belts or poly-v belts, are now the standard in most modern vehicles. They are flat belts with multiple V-shaped ribs running lengthwise along the underside. A single serpentine belt drives multiple accessories, hence the name “serpentine” as it “snakes” around various pulleys.

Advantages of Serpentine Belts:

- More efficient: Provide better grip and reduced slippage due to the larger contact area and ribbed design.

- Longer lifespan: Generally last longer than V-belts.

- Less maintenance: Often use automatic tensioners, reducing the need for manual adjustments.

- Drives multiple accessories: Simplifies engine design and reduces the number of belts needed.

- Wear indicators: Some modern serpentine belts, like the Optibelt RBK mentioned in the original article, have wear indicators that make it easier to visually assess belt condition.

Recognizing the Signs of a Failing Drive Belt

Knowing the symptoms of a worn or failing drive belt can help you address the problem before it leads to more serious issues. While manufacturer recommendations vary, most suggest drive belt replacement around every 60,000 to 100,000 miles. However, keep an eye out for these warning signs:

- Squealing or Squeaking Noises: This is a common symptom, often heard at startup or during acceleration. It’s usually caused by belt slippage due to wear, glazing, or loss of tension.

- Visible Cracks, Wear, or Fraying: Inspect the belt for any visible damage. Cracks across the ribs, fraying edges, or missing chunks of rubber indicate the belt is deteriorating and needs replacement. Some belts have wear indicators – for example, red markings becoming visible, as mentioned with RBK belts, signal wear.

- Engine Overheating: If the drive belt powers the water pump or radiator fan, a failure can lead to overheating. Keep an eye on your car’s temperature gauge.

- Air Conditioning Malfunction: If your AC is blowing warm air, especially on hot days, it could be due to a slipping or broken drive belt not powering the AC compressor.

- Power Steering Problems: Difficulty steering, especially at low speeds, can indicate the power steering pump is not being driven properly. The steering may feel heavy or unresponsive.

- Battery Warning Light: If the alternator isn’t being powered, your battery won’t charge, and the battery warning light on your dashboard might illuminate.

- Visibly Worn Pulleys or Tensioner: While inspecting the belt, also check the pulleys and tensioner for signs of wear, damage, or misalignment. A faulty tensioner can cause premature belt wear.

If you notice any of these symptoms, it’s crucial to inspect your drive belt and the related systems as soon as possible.

Drive Belt Maintenance and Replacement

Regular maintenance is key to preventing drive belt failures. Here are some tips:

- Follow Manufacturer Recommendations: Consult your car’s owner’s manual for the recommended drive belt inspection and replacement intervals.

- Regular Visual Inspections: Periodically check the drive belt for cracks, wear, fraying, and proper tension. You can usually do this yourself by visually inspecting the belt in the engine bay.

- Listen for Noises: Pay attention to any unusual noises, like squealing or chirping, coming from the engine area.

- Professional Inspections: During routine servicing, ask your mechanic to inspect the drive belt’s condition.

When replacement is necessary, it’s generally a straightforward and relatively inexpensive repair. However, it’s important to:

- Use Quality Replacement Belts: Choose belts from reputable brands that meet or exceed OEM specifications.

- Replace the Tensioner and Idler Pulleys (If Necessary): If the tensioner or idler pulleys are worn or noisy, they should be replaced at the same time as the belt to ensure proper belt function and longevity.

- Ensure Correct Tension: Proper belt tension is crucial for performance and belt life. Too loose, and the belt will slip; too tight, and it can damage bearings and shorten belt life. Modern cars often use automatic tensioners, but older vehicles may require manual adjustment.

What to Do Next?

If you suspect a problem with your drive belt, or if it’s nearing its recommended replacement interval, it’s best to have it inspected by a qualified mechanic. Ignoring a worn drive belt can lead to breakdowns and potential damage to other components.

If you’re unsure about the condition of your drive belt or are experiencing any of the symptoms mentioned above, consult with a trusted automotive service center. They can properly diagnose the issue, recommend the appropriate solution, and ensure your car remains reliable and safe to drive. Don’t wait for a complete drive belt failure – preventative maintenance is always the best approach.