Positive Crankcase Ventilation (PCV) systems play a crucial role in maintaining the health and performance of any car engine, and this is especially true for Turbo Cars. While the basic function of a PCV system remains consistent across engine types, turbocharging introduces unique challenges and considerations. Let’s delve into the specifics of PCV systems in turbo cars, addressing common questions and best practices for optimal engine operation.

What is a PCV System and Why Is It Important?

At its core, a PCV system is designed to remove harmful gases and vapors from the engine’s crankcase. These byproducts, often referred to as “blow-by,” are a result of combustion gases and unburnt fuel escaping past the piston rings and entering the crankcase. If left unchecked, these gases can contaminate engine oil, leading to sludge buildup, corrosion, and ultimately, reduced engine lifespan and performance. The PCV system prevents this by venting these gases back into the intake manifold to be re-burned during the combustion process. This not only helps keep the engine clean but also reduces harmful emissions.

PCV Challenges in Turbocharged Engines

Turbocharged engines introduce a significant factor that naturally aspirated engines don’t typically encounter: boost pressure. In a naturally aspirated engine, the intake manifold consistently operates under vacuum, which is essential for the standard PCV valve to function correctly. The vacuum pulls crankcase gases into the intake. However, when a turbocharger kicks in and generates boost, the intake manifold pressure becomes positive. This positive pressure can disrupt the normal operation of a standard PCV system, potentially leading to several issues.

The Impact of Boost Pressure

Under boost conditions, a conventional PCV valve connected directly to the intake manifold might not close completely. If it fails to seal properly, boost pressure can enter the crankcase. Introducing boost pressure into the crankcase is detrimental as it counteracts the system’s intended function of relieving pressure. This pressurization can force oil past engine seals, leading to leaks – a concern raised by the original poster experiencing rear main seal and oil pan leaks. Furthermore, uncontrolled crankcase pressure can reduce engine efficiency and potentially cause damage over time.

Dual Vent Systems and Catch Can Solutions

To address the challenges posed by boost pressure, turbo car PCV systems often incorporate specific design features, including dual vent setups and catch cans.

Dual Vent Configuration

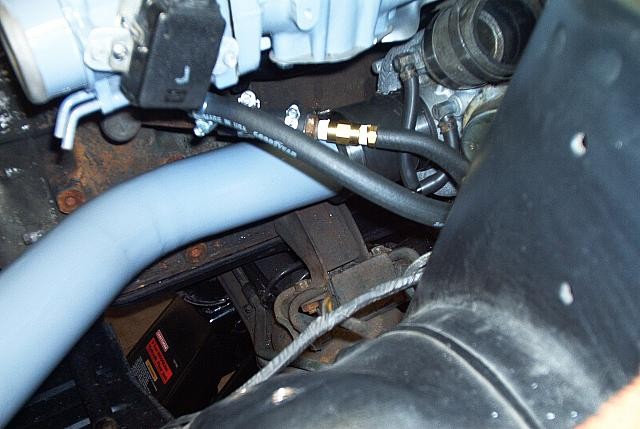

A common strategy in turbo cars is to employ a dual vent system. This typically involves two vent lines originating from the crankcase or valve cover. One line is connected to the intake manifold, usually via a PCV valve, to function under vacuum conditions when the engine is not under boost. The second vent is positioned upstream of the turbocharger, before the throttle body and air filter. This pre-turbo vent takes advantage of the vacuum created at the turbo inlet. Even when the intake manifold is pressurized under boost, the turbo inlet maintains a vacuum, ensuring continuous crankcase ventilation.

This dual-vent approach ensures that the crankcase is always under vacuum, whether the engine is idling, cruising, or under full boost. As suggested in the forum, some setups use a check valve in conjunction with the PCV valve to further prevent boost from entering the crankcase through the intake manifold line when under pressure.

The Role of Catch Cans

Another important component often integrated into turbo car PCV systems is the catch can. As the name suggests, a catch can is designed to trap and collect oil mist, fuel vapors, and moisture that are carried along with the crankcase gases. Without a catch can, these contaminants would be routed back into the intake, potentially leading to carbon buildup on intake valves, reduced intercooler efficiency, and even detonation.

Installing a catch can in the PCV system, typically in the line between the crankcase vent and the intake manifold (and sometimes in the pre-turbo vent line as well), helps to filter out these unwanted substances. This keeps the intake system cleaner, maintains optimal combustion, and can contribute to improved engine longevity. As discussed in the forum, while not strictly necessary for all turbo cars, a catch can is a beneficial addition, especially in engines prone to blow-by or those driven aggressively.

Addressing Oil Leaks and PCV System Troubleshooting

The original poster’s concern about oil leaks possibly stemming from PCV issues is valid, although as some forum members pointed out, it’s less likely to be the primary cause of rear main seal or oil pan leaks. While a severely clogged or malfunctioning PCV system could contribute to increased crankcase pressure, leading to leaks, it’s more probable that seal degradation due to age or improper installation are the culprits in older vehicles.

However, ensuring a properly functioning PCV system is still crucial. If you suspect PCV problems in your turbo car, consider the following:

- Inspect PCV valve: Check for clogs or sticking. Replace it at regular intervals as part of routine maintenance.

- Examine vent lines: Look for cracks, blockages, or loose connections.

- Consider a catch can: If you notice excessive oil in your intake or suspect blow-by, installing a catch can is a worthwhile upgrade.

- Verify dual vent setup: Ensure your turbo car utilizes a proper dual vent system to handle both vacuum and boost conditions effectively.

In Conclusion

For turbo car owners, understanding the nuances of the PCV system is essential for maintaining engine health and performance. Turbocharging necessitates a more sophisticated PCV design than naturally aspirated engines, primarily to manage boost pressure effectively. Dual vent systems and catch cans are common solutions employed to ensure consistent crankcase ventilation and prevent harmful contaminants from recirculating through the intake. While PCV issues might not be the direct cause of all oil leaks, a properly functioning PCV system is a critical component in the overall health and longevity of any turbo car engine. Regular inspection and maintenance of your PCV system will contribute to a cleaner engine, reduced emissions, and reliable performance for years to come.